Big promotion for chopped /short fiber insulation felt:

Size: 1600*1600*50mm; After trimming, the size is 1550-1550-50mm min.

Price: 67.8$/kgs, we have much stocks, so we want to sell with discount price. If with big quantity order, we can still give more discount.

Stock value: 400-500 sheets

Preparation method of new short fiber insulation felt and barrel for high temperature furnace:

First, according to the specifications of the thermal insulation felt, tube product, design a forming mold composed of an inner mold and an outer mold that are set together. The water is mixed evenly according to the ratio of 1~10:1~10:10~1000 parts by mass, while stirring, the forming mold is hoisted into the mixed slurry, the vacuum system is turned on, and the short fibers are realized on the forming mold along the direction of the water flow. Fiber is distributed and shaped, and finally the formed insulation felt tube is cured under inert gas protection or vacuum conditions, carbonization treatment, mold release, and high temperature treatment to obtain a high-performance insulation felt tube; similar to the prior art. In contrast, the invention has the advantages of short fiber distribution and orientation, excellent heat preservation performance, simple equipment, one-time molding of fiber and resin, and low cost.

Search keywords: insulation felt, molding mold, short fiber, vacuum system, high temperature furnace, inner mold, resin, preparation, molding, inert gas protection, heat preservation performance, high temperature treatment, curing treatment, carbonization treatment, fiber distribution, one-time molding, vacuum Conditions, carbon fiber, graphite felt, hard felt, rigid graphite felt.

The preparation method of the new short fiber insulation felt /tube for high temperature furnace is characterized in that:

It includes the following steps:

(1) According to the specifications of the thermal insulation felt tube product, the forming mold is designed. The forming mold is composed of an inner mold and an outer mold set together. Both the inner mold and the outer mold have a cylindrical structure, and the inner and outer molds are evenly distributed with a number of holes. The hole density is 500~2000/m2, the center of the inner mold is connected to a pumping pipe, and the pumping pipe is connected to a vacuum system;

(2) The carbon fiber, resin and pure water are mixed uniformly in a ratio of 1~10:1~10:10~1000 parts by mass to make the solution dispersibility good, and a single fiber is suspended in water without agglomeration;

(3) Hang the forming mold into the mixed slurry while stirring, turn on the vacuum system, and the short fibers follow the direction of the water flow to achieve fiber distribution and shaping on the forming mold. After all the water flows out without dripping, the short fibers are shaped and distributed. The forming of the insulation felt tube is completed;

(4) Put the formed insulation felt tube together with the forming mold into the oven, and carry out curing treatment, carbonization treatment, mold release and high temperature treatment under inert gas protection or vacuum conditions to obtain a high-performance insulation felt tube , The curing treatment temperature is 140~220°C, the curing time is 5~15h, and the heat preservation is 2~6h; the carbonization treatment temperature is 500~900°C, the carbonization time is 50~70h, and the heat preservation is 2~6h; the high temperature treatment temperature The temperature is 1700~2400℃, the high temperature treatment time is 24~48h, and the heat preservation is 2~6h.

Properties of short fiber insulation felt:

| Short fiber insulation felt /rigid board | |||

| Item | Unit | Properties | tested |

| density | g/cm3 | 0.13-0.16 | 0.15 |

| Thermal conductivity | w/(mk) | ≤0.2(1000℃) | 0.18 |

| Compressive strength | MPa | ≥0.2 | 0.34 |

| Flexural strength | MPa | ≥3.5 | 4.9 |

| Ash content | ppm | ≤3000 | 1487 |

See video of short fiber insulation felt: https://www.youtube.com/watch?v=GHfn07s4Uxs

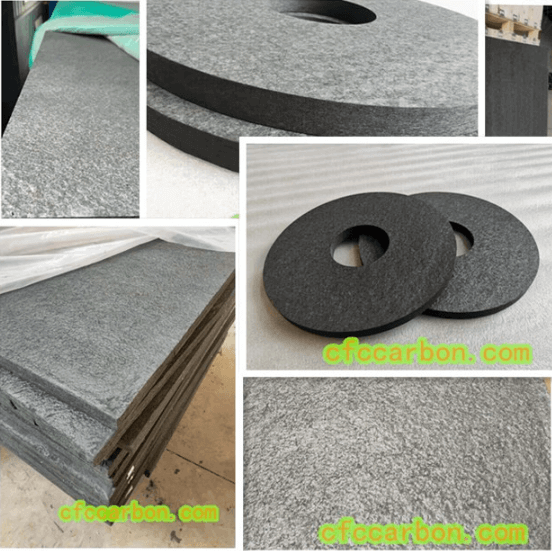

Photos of short fiber insulation rigid felt:

chopped-short fiber integral insulation felt-rigid felt

Photos-short fiber integral insulation felt-rigid felt (8)

Photos-short fiber integral insulation felt-rigid felt (7)

Related products: