There are many types of graphite plates, but there are generally two types: one is cut and processed directly from raw materials; the other is resin graphite plates, which is cut from raw materials, impregnated with resin or other

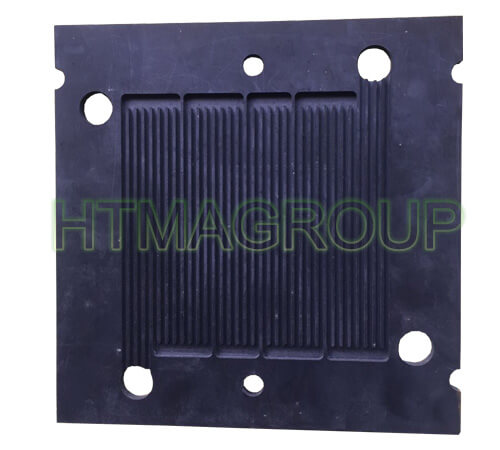

graphite bipolar plates

materials, and then processed.

Compared with other materials, graphite sheet has better chemical stability. Therefore, it can be widely used as an anti-corrosion structural material to replace black or non-ferrous metal materials, especially to replace stainless steel, and its effect is more significant.

Graphite plates are not subject to oxidation in the air below 400T. Graphite is very stable in all chemical media except for strong oxidizing acids, such as nitric acid, fuming sulfuric acid, chromic acid, aqua regia, nansu and other chemical media. .

Graphite plates are widely used in metallurgy, electronics, machinery, chemical, electrochemical and other industries. Graphite board is so widely used, so what characteristics and advantages does it have?

1. The ease of processing of graphite plates: Graphite plates can be die-cut into different sizes, shapes and thicknesses, and die-cut flat plates can be provided, with thicknesses ranging from 0.05 to 1.5m.

2. The high temperature resistance of the graphite plate: The high temperature of graphite plate can reach 400℃, and the lower temperature can be lower than -40℃.

Graphite sheet

3. High thermal conductivity of graphite board: The in-plane thermal conductivity of graphite board can reach 1500W/mK. The thermal resistance is 40% lower than aluminum and 20% lower than copper.

4. The flexibility of graphite board: Graphite board can be easily made into a laminate with metal, insulating layer or double-sided tape, which increases design flexibility and can have an adhesive on the back.

5. Lightness and thinness of graphite plate: Graphite plate is 30% lighter than aluminum of the same size and 80% lighter than copper.

6. The ease of use of graphite plates: graphite heat sinks can be smoothly attached to any flat and curved surfaces.

To sum up, graphite plates have good electrical conductivity, high temperature resistance, acid and alkali corrosion resistance and easy processing, so they are widely used in metallurgy, chemical, electrochemical and other industries.

The impregnated graphite sheets produced by our company are made of high-quality graphite carbon materials and added with organic compounds with strong acid resistance. It is refined by high-pressure forming, vacuum impregnation, and high-temperature heat treatment. It has extraordinary acid and temperature resistance. It is an ideal lining material for phosphoric acid reaction tanks and phosphoric acid storage tanks in the chemical industry. The impregnated graphite board has the following characteristics:

1, excellent corrosion resistance

Graphite plate adopts excellent graphite carbon material, adding organic compound with strong acid resistance, which effectively reduces the porosity of the product and increases the volume density of the product, so the mouthpiece has excellent corrosion resistance and strong wear resistance performance.

2, stable performance, strong durability

The impregnated graphite board uses high-strength organic glue as the bonding agent and introduces high-tech additives, so the product has high strength, good wear resistance, and extremely stable structure. The product structure does not change with temperature changes.

3, precise dimensions

Using compression molding, the product has good molding quality, accurate shape and size, and can produce special products according to user requirements, which can fully meet the requirements of construction and masonry technology.

4. The coefficient of thermal expansion is small, and the linear rate of change is low. When used within the range of 180 degrees, it has stable performance and strong durability.

Impregnated graphite plates are also used in different fields: graphite rotary sheets, impregnated resin graphite, used in vacuum pumps or other pump valves; graphite bipolar plates, impregnated graphite, used in the field of fuel cells.

Other emerging fields are also considering and studying how to use new graphite materials to replace original materials, which greatly improves the cost performance, saves equipment maintenance time and costs, and improves production efficiency and economic benefits.