Vacuum pump carbon vane is used inside the dry pump, its the important part for the pump to get vacuum. As the vacuum pump carbon vane is produced from the graphite material, and the oil-free lubrication environment of pump, so the vacuum pump carbon vane has good performance in high temperature and wear resistance.

Vacuum pump carbon vane has the following characteristics:

1, has a very high elastic limit, anti-fatigue mild excellent to adapt to high-intensity pump operation

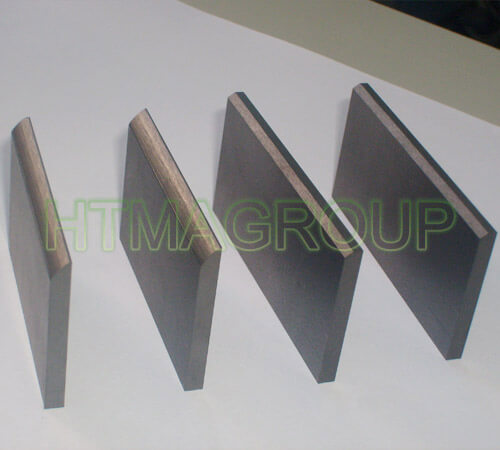

mechanical carbon vane

2, the main element of the carbon material is carbon, that is free-shaped graphite, the port is dark gray, resulting in vacuum pump carbon vane with higher hardness, more excellent wear resistance.

3, the use of rational design of product shape, reduce surface roughness, and the use of surface treatment to provide vacuum pump carbon film anti-fatigue properties

4, the vacuum pump carbon vane is self-lubricated, can adapt to long time high-temperature operation.

CFCCARBON LTD can produce other air pump carbon vanes too, OEM available.

Vacuum pump carbon vane’s replacement:

First, fracture

Parts under the action of the extra load, the vacuum pump carbon vane can break when a dangerous cross-section of the stress exceeds the strength limit of the parts. in addition to the material itself, This phenomenon occurs , in the assembly of our products are also related to the action. Therefore, we must pay attention to the assembly of the vacuum pump the direction of the selection of carbon vanes and vacuum pump carbon film and the rotor cylinder with the gap between the control. To prevent the phenomenon of fracture due to human factors.

graphite vane manufacturer in china

Second, surface damage

Vacuum pump carbon film as a result of long-term high-speed operation, coupled with wear, corrosion, contact fatigue and other reasons, resulting in vacuum pump carbon film exceeds the allowable value and failure. Carbon film products such consumables, we must develop maintenance cycle, in order to better ensure the performance of the pump play.

Third, the material changes lead to poor performance

Due to metallurgical elements, chemical effects, radiation effects, high-temperature long-term effect caused by vacuum pump carbon film material changes, resulting in lower material properties.

Fourth, damage to normal working conditions caused by failure

Vacuum pump carbon sheet need certain conditions to work properly, such as: with the gap and accuracy, and only with the gap and accuracy to meet the requirements, the vacuum pump carbon film to play its effectiveness.

In summary, the vacuum pump carbon vane failure are produced under specific conditions, its caused by failure of many factors, involving the vacuum pump carbon processing technology, assembly and maintenance, in short, summarized as personnel, equipment, materials , Process, management, environmental conditions. So to make the performance of vacuum pump carbon vane more excellent and thus improve the performance of the pump, we can proceed from the above aspects.

We can provide a variety of specifications for the vacuum pump graphite vanes, carbon vanes. OEM available with customers’ drawings and requirements.

【Special Note】

Graphite products, graphite parts are produced according to the order, there is no much stocks, so the price depends on customer requirements (specifications, quantity, technology, materials) separate accounting, please contact us for more.

related news /articles:

Graphite vane, vacuum pump graphite vane, blade manufacturer

Electrical and mechanical applications of molded graphite

Carbon brush and brush materials-electrical carbon (2)