Thermal conductivity: The thermal conductivity of the ideal graphite crystal was reviewed in Ch.3, sec. 4.3. The mechanism of heat transfer is by lattice vibration and the thermal conductivity is approximately 200 times greater in the basal plane than across the planes, thus reflecting the anisotropy of the graphite crystal.

This anisotropy is less pronounced in molded graphites and carbon materials and the thermal conductivity is more isotropic. Typical values for graphite and other high-conductivity materials are given in table 5.7.

Table 5.7. Thermal conductivity of molded carbon, graphite and high-conductivity metals

| W/m.K at 20C | |

| Electrographite (from petroleum coke)

Electrographite (from lampblack) Carbon Diamond Silver Copper |

159

31.4 8 1800 420 385 |

The relationship between the thermal conductivity of molded graphite and temperature is similar to that of single-

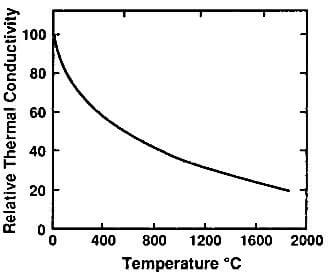

fig.5.8-relative thermal conductivity of molded graphite as a function of temperature

crystal graphite. After an initial increasing, the conductivity decreases and, at 2000C, it is an order of magnitude lower than at room temperature. This relationship is shown in Fig. 5.8.

Thermal expansion: The thermal expansion of the graphite crystal was reviewed in Ch.3, sec. 4.4. This expansion has a marked anisotropy. It is low in the ab directions but an order of magnitude higher in the c direction.

Molded-graphite materials have a much more isotropic thermal expansion than the graphite crystal, since the crystallites are randomly oriented and the inherent porosity absorbs a portion of the expansion. Still some degree of anisotropy remains in extruded- and compression-molded graphites and the coefficient of thermal expansion across the grain is typically 50% higher than with the grain. The CTE of isostatically molded graphite can be essentially isotropic.

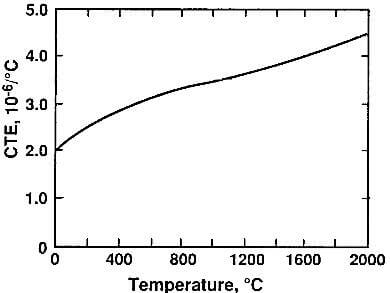

The CTE of molded graphite increases with temperature, as shown in fig.5.9. At 1500C, it is approximately twice

fig.5.9-average CTE of graphite as a function of temperature.

the room temperature value. Yet, it remains low compared to most other structural materials as shown in table 5.8.

Table 5.8. Thermal expansion of typical molded graphite and other materials.

| Material | CTE

M/mC-10-6 100-600C |

| Extruded grpahite

With grain Across grain Aluminum Copper Tungsten |

1.8-2.9 3.2-5.0 3.2-5.7 23.5 (at 25C) 16.6 (at 25C) 4.5 (at 25C) |

The thermal expansion of molded graphite is an important property since many applications involve high temperature, and expansion values must be known accurately.

Thermal shock: The low modulus, high thermal conductivity, and low thermal expansion combine to give molded graphite excellent thermal-shock resistance. It is difficult to rupture the material by thermal shock alone.