Early work showed that the thermo-oxidative instability of carbon fibers affected the stability of high temperature laminates at 300C.

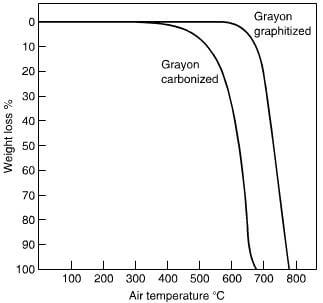

Carbon fibers oxidize in air and figure 20.29 shows the weight loss of Rayon precursor carbon fiber, where the

fig.20.29-carbonized rayon carbon fiber weight loss vs temperature in air

more graphitic version has the best oxidation resistance. The thermal stability of oxidized PAN and PAN based carbon fiber is compared with an aramid. An oxidized PAN fiber will lose more weight as the temperature increases and the reported loss will include any absorbed moisture in the oxidized PAN.

The thermal oxidative behavior in air at 250 and 300C of several grades of PAN based carbon fibers was studied by Gourdin and the weight losses at 250 and 300C as a function of time in air. Gourdin’s results did not support any correlation of thermo-oxidative properties of the fiber with the Na content, since Hercules AS-4 fiber had a high Na content, but good thermo-oxidative resistance, whereas Toray T300B had a low Na content but poor stability. However, fibers produced at highest production temperatures, such as HTS and HMS, did have the best thermo-oxidative resistance.

The oxidation rate of various carbon fibers heated for 3h in air at 500C does show some relationship with the Na content and certainly fibers with low Na showed the best thermo-oxidative resistance and are associated with fibers with the highest carbon content.

Page and Duquette showed that the oxidation resistance of the carbon fibers in a glass matrix was related to the microstructure of the glass reinforcement and the adherence of the glass to the carbon fibers. Coating the fibers with a SiC precursor by CVD was shown to improve the oxidation resistance of the fibers.