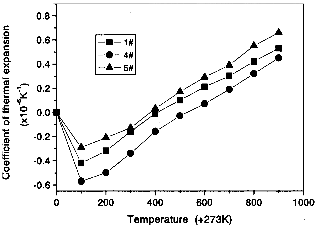

Fig.4 demonstrates the effect of the PyC microstructure on the CTE of the C/C composites. The microstructure of the PyC has no evident effect on the CTE, and that of composite 5# is higher than that of composites 1# and 4# under the same conditions. For composites possessing the same preform, except the microscopically pores between their PyC is different, the PyC themselves contain various microscopical pores leading to different densities, so that they have a different effect on the CTE of the C/C composites. Generally, the density of SL PyC is larger than that of ISO and smaller than that of RL PyC, as a result its ability for inducing the negative expansion is better than that of RL and that of ISO PyC. In composite 5# the PyC is mainly composed of more complete and compact RL, so the composite 5# possesses the highest CTE. Because the PyC in the samples 1# and 4# possesses SL and ISO tissue, respectively, their CTE is lower under the same conditions.

fig.4-effect of microstructure of PyC on CTE for the CC composites

Is spite of diverse structures, the five C/C composites are all made up of carbon atom, and their atom spacing is similar, so that their thermal expansion behaviors possess the same change trend with the temperature. This is responsible for their almost same slopes on the CTE vs. T curves.

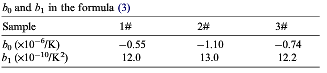

The relationships between the CTE of the five C/C composites and temperature can be expressed by the formula

α=b0 + b1T, (3)

b0 and b1 are shown in table 3. b0 reflects effect of the composite porosity, the structures of the PyC and preforms. b1 values are about 12-14 × 10-10/K2

table.3-b0 and b1 in the formula