Isostatic pressing technology is a forming process. Compared to the normal molding technology, it has the following characteristics:

A.Isostatic pressing products is with high density, generally more than one-way and two-way molding products.The relative density of hot isostatic pressing products can reach 99.8% ~ 99.9%.

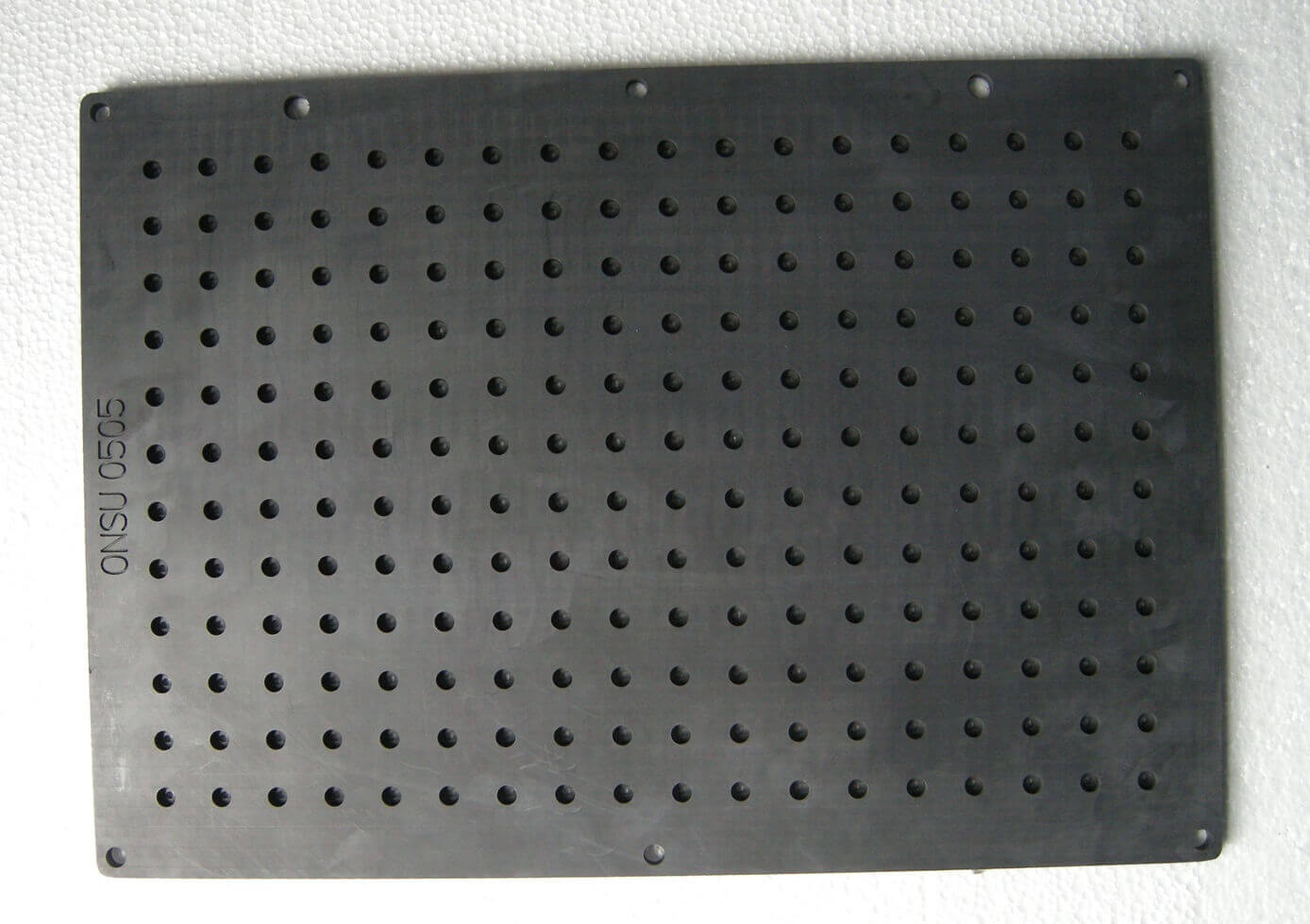

high purity isostatic graphite CNC machining parts plates material manufacturer factory China (1)

- The density of products is uniform. In the molding method, whether it is one-way, or two-way molded machine, there will be different distribution on density. This difference in density when making complex shape products, often up to 10% or more. This is caused by the friction between the powder and the steel mold. The isostatic pressure from the fluid medium is equal in all directions. The powder and the package are with little relative movement, friction between them is small, the pressure is only slightly decreased, the density difference is generally only 1% or less, therefore, we can considered that the bulk density is uniform.

C – because the density is uniform, the production of long diameter can be unrestricted, which is good to the production of rod-shaped, tubular thin and long products.

- In the isostatic pressing process, there is no need to add lubricant material in the powder, so not only reduces the pollution of products, but also simplifies the manufacturing process.

- Isostatic pressing products with excellent performance, short production cycle, and a wide range of applications. Isostatic pressing process has the disadvantage of low process efficiency, expensive equipments.

there is two ways of Cold isostatic pressing, dry and wet bags way. Accordingly, the structure of the isostatic pressing machine is different.

- wet bag method of rhe isostatic pressing

Put the powder directly into the plastic bag, hit the liquid pressure medium, and liquid contact. So called wet bag method. This method can easily change the shape and size of plastic wrap, with flexibility of production. but its only Suitable for small-scale production. Each time we can carry out bagging, unloading bag operation, but the production efficiency is not high, with no continuous large-scale production.

isostatic graphite rods

- Dry bag method of Isostatic pressing

We put the rubber bag first in the cylinder, and don’t remove it when its working. and the powder is loaded into an additional molded plastic bag. then put Into the pressurized rubber bag, not in contact with the liquid direction. So called dry bag method. This method can be continuous operation, that is, open the lid. Charge from the hopper. And then covered by the upper cover pressurized by. When the material is ready, we open the top cover. Through the bottom bar to kick it out from the top. The operation cycle is short, suitable for mass production. But product size are limited. Because the pressure plastic mold can not be replaced frequently.

The wet bag method is extensively used in industrial production.

CFCCARBON LTD can produce large amount of isostatic graphite with stable and reliable quality, Our Products were sold throughout the country and exported to Europe, America, Southeast Asia and other countries and regions which enjoy a high reputation all over the world.

We use the CIP way. Its called cold isostatic pressing.

All sizes available, standard bulk density: 1.78g/cm3; 1.85g/cm3; 1.90g/cm3 min.

Data sheet as bellow:

| Type | Grain size um | Bulk density (g/cm3) | Hardness (shore) | Specific Resistance (μΩ•m) | Bending Strength (MPa) | Compressive Strength (MPa) | Thermal Conductivity (W/m•K)) | C.T.E (100-600)℃ (10-6/℃) | Ash Content (%) | Porosity % |

| IFS-1A | 14 | 1.68 | 51 | 13 | 38 | 86 | 0.05 | 18 | ||

| IFS-1B | 14 | 1.78 | 56 | 9–10 | 43 | 85 | 0.05 | 16 | ||

| IFS-2A | 12 | 1.85 | 46 | 9–12 | 45 | 85 | 120 | 2.5 | 0.04 | |

| IFS-2B | 14 | 1.85 | 48 | 8.5 | 46 | 85 | 139 | 4.75 | 0.05 | 13 |

| IFS-H6 | 14 | 1.9 | 53 | 8–9 | 55 | 95 | 140 | 5.1 | 0.05 | 11 |

| IFS-W6 | 8 | 1.91 | 53 | 8–9 | 58 | 100 | 140 | 5.1 | 0.05 | 11 |

| IFS-H7 | 8 | 1.85 | 65 | 11–13 | 51 | 115 | 85 | 5.6 | 0.05 | 11 |

| IFS-H8 | 8 | 1.91 | 70 | 11–13 | 60 | 135 | 85 | 5.85 | 0.05 | 11 |

sizes: in mm. Φ567*520; Φ558*521; Φ650*470; Φ755*638; Φ560*560; Φ550*630; Φ630*1070; Φ490*190; 755*365*365; 755*265*265; d680*800

Contact Us

ADD: Yizhuang Economic Development Zone, Beijing 100176, China.

Fax: +86 10 80828912

Website: www.cfccarbon.com

Email: potter@cfccarbon.com

related news /articles:

Big promotion for isostatic graphite rods, size D100-400mm

graphite pipe, graphite tube

graphite rods, graphite blocks