The five C/C composites are made of the CF, PyC, and pores (Fig.2). The CF structure is the skin-core structure. The crystallites of PyC are arranged in the strip on the surface of the CF, in which carbon atom plane are parallel to the direction of fiber axis. In the process of chemical vapor deposition, the small pores between the CF are filled by the PyC, but the larger pores between the fiber bundles are difficult to be densified because of slow deposition or surface crust.

Fig.2-microstructures-of-five-CC-composite.-

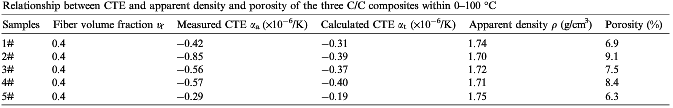

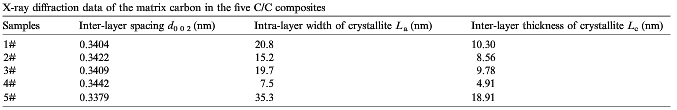

These remained pores result in the discontinuous distribution of PyC. The five composites possess the different porosity owing to the different preform architectures and manufacture technologies (table 1), and there are also large differences in the growth characteristic of PyC such as the crystallite size and orderliness degree, shown in Table 2.

Table 1.-relationship between CTE and density of CC composite

Table 2.-X-ray diffraction data of the matrix carbon in the five CC composites

The microstructures of PyC in the five composites are shown in Fig.2 under the polarized light conditions. Composites 1#, 4#, and 5#, have the same preform architectures and the different PyC microstructures. In composites 5#, the PyC is mainly composed of rough laminar tissue, which grows around the CF in the form of ringed multilayer, but in composites 1# and 4#, the PyC consists chiefly of the smooth laminar and isotropic tissue, respectively. In composites 3#, the PyC is filled well in the fiber bundles and between the carbon cloth layers, and the PyC is made mainly up of SL tissue. As for composite 2#, it is composed of the chopped fiber, the resin carbon, and PyC. The resin carbon possesses ISO tissue, and the PyC exists around the resin carbon, but it is weak in optical activity and loose in the structures with leading to the largest discontinuity of the matrix carbon. The microstructures of the matrix carbon and the preform architectures result in the different thermal properties of the five C/C composites.