The mechanical properties are directional and vary with the grain and across the grain. Isostatic pressing gives the most uniform product with the highest density and improved strength, but its an expensive route. The extruded graphite aligns the grain in the direction of extrusion, yielding a product with anisotropic properties, but is relatively cheap and is used for the manufacture of parts with constant cross-section, such as electrodes. Graphite produced by compression molding has the grain perpendicular to the molded direction, having an intermediate cost and is used for making parts with complex shape such as dies or bearings. Sections can, on demand, be molded up to 1.8m diameter.

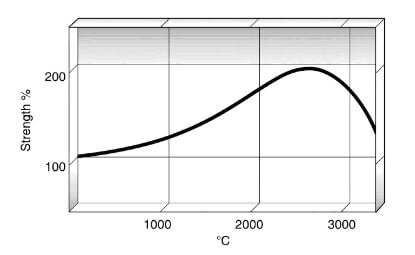

Molded graphite is glass-like in behavior and at ambient temperature, fails in brittle manner. However, at higher temperatures, is is effect annealed and, unlike other materials, the strength increases with rising temperature. The chart bellow shows how the flexural strength at

relation of flexual strength and temperature

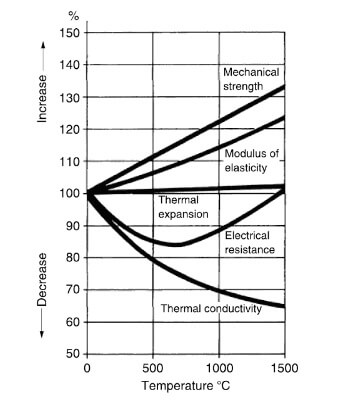

room temperature is almost doubled when the temperature is increased to 2500C, while the chart bellow shows the effect of temperature on the other properties.

effect of temperature on graphite properties.

Generally, the smaller the diameter of the molded section, higher the mechanical properties. Consequently, it is important to select the correct diameter for an electrode, as otherwise the superior properties of the outermost section will be machined way. Typical manufacturer’s properties of graphite will show the effect of the method of manufacture, grain size, direction of grain and the size of the section.

CFCCARBON LTD is a manufacturer of graphite material and products in china, with stable and reliable quality. Our material: Moled graphite, isostaitc graphite, vibration graphite, extruded graphite, mechanical graphite and carbon brush materials. Products: machined graphite parts, graphite pipes, mechanical seal and bearing, carbon brushes and graphite bipolar plate..