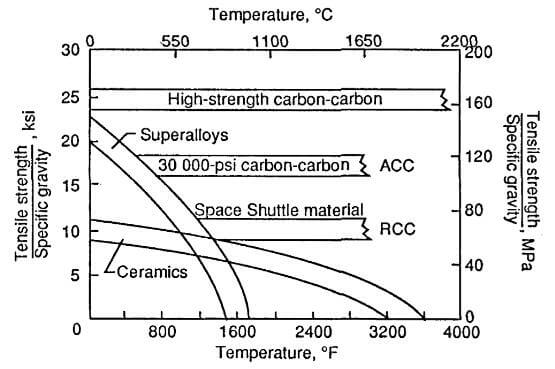

The extreme thermomechanical requirements of the Space Shuttle have been the impetus for evaluating properties of low-density CC. The use of CC on the nose cap and leading edges of the Space Shuttle makes it imperative to know as much as possible about all the characteristics of this material. The effect of temperature on the ratio of tensile strength to density for several classes of high-temperature material is shown in figure 11.

strength-to-density ratio for several classes of high-temperature materials

The major advantage of CC materials for high-temperature applications is that they do not lose strength as the use temperature is increased. This property is in contrast to other materials such as superalloys and ceramics. Figure 11 shows three levels of CC strength efficiency. The first, labeled Space Shuttle material, is the strength level of the reusable carbon-carbon material used in Space Shuttle thermal protection system. Even though this material is made with low-strength carbon fibers, its strength efficiency is superior to both superalloys and ceramics at >1000C. Development of advanced carbon-carbon composites has produced a material that is twice as strong as the CC composite first put on the Space Shuttle. The ACC material is made using woven carbon cloth. When unidirectional carbon fiber tapes are interplied with woven cloth to create a hybrid ACC, its strength in as least one direction can be increased to >345MPa. Current data on thermomechanical and thermochemical properties of some of the advanced CC system show that material composition, oxidation resistance, processing, joining, and fiber architecture are producing noticeable improvements in CC materials and strictures.

CFCCARBON LTD is the top manufacturer of carbon carbon composite | C/C composite in china, with stable and reliable quality. Our products: 2D,2.5D,3D,4D carbon composite, with density from 1.40-1.95g/cm3, with CVD, CVI processing, or pitch based carbon composite. also, we produce carbon ceramic composite material and products.