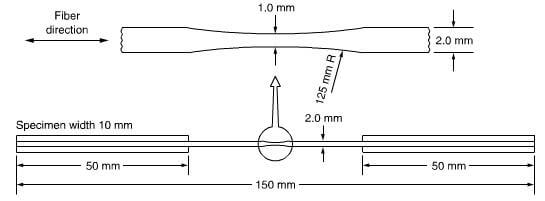

To ensure that the tensile specimen will break in the gage length and not at the grips, the specimen is waisted (Fig. 17.37) using a high speed (20,000 rpm) router cutter. It has been found advantageous to replace the

unidirectional tensile composite specimen

cutter with a small grindstone of the same diameter. The specimen is held in a special template, which the cutter follows exactly as it shapes the tensile specimen. Alternatively, instead of using a router cutter, a 125

waisting contour of unidirectional cfrp tensile specimen

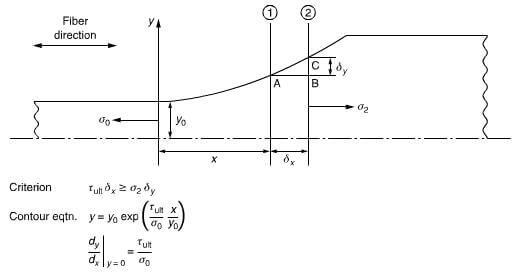

mm radius grindstone can be used. This radius was established theoretically by RAE and adjusted practically, so that the same radius could be used for a compression specimen without the latter failing in a buckling mode. The contour equation (Fig. 17.39) developed by RAE is as bellow:

RAE equation

Fig 17.40 shows the mode of failure with different fiber types when using a 125 mm radius necked portion and the evidence does suggest that a radius of 175 mm would better accommodate AU and HTU fibers.

When breaking tensile specimens, the operator should be protected against flying debris with a protective screen, which can be a sliding window attached to the frame of the test machine.