Graphite bipolar plates are an important component of fuel cells. The graphite bipolar plates produced by our company have been sold overseas, with stable quality, relatively low prices, short delivery times, strict production

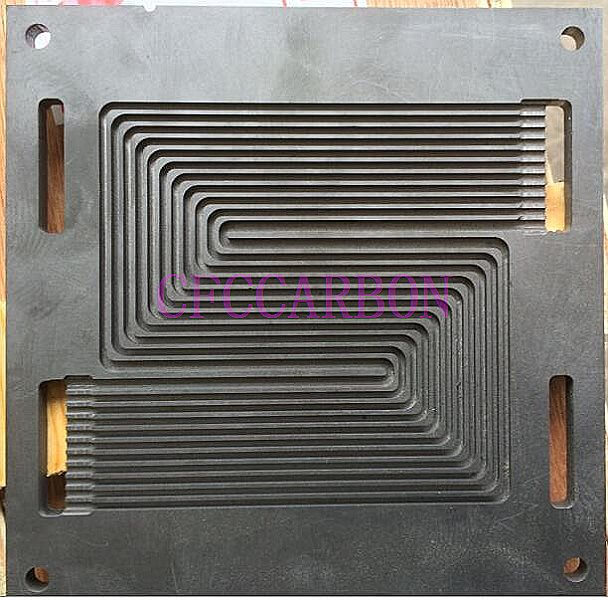

bipolar graphite plate

and processing technology, strict tolerance control, and high processing accuracy.

Market status of graphite bipolar plates:

The bipolar plate made of graphite material has the characteristics of good electrical conductivity, thermal conductivity, stability and corrosion resistance, and has high dimensional accuracy, good structural stability, easy flow channels, high chemical stability, hydrogen, air , The refrigerant three-cavity structure can also be independently designed, so that it has advantages in life and reliability, and can fully meet the current requirements of buses and logistics vehicles.

However, due to poor mechanical properties (compared to other types of bipolar plates), brittleness, easy breakage, and difficulty in machining, the cost is high. According to reports, at this stage, the processing fee for each 500cm2 graphite bipolar plate is more than $80, accounting for more than 50% of the cost of the bipolar plate. Graphite plate stacks cannot meet the needs of passenger cars in terms of specific power density, mass production cost, and low-temperature startup. At present, they are only used in some commercial vehicle fields, and their use areas are limited.

Most domestic companies started with graphite products. The time to enter the fuel cell field was concentrated between 2006 and 2011. After that, they took advantage of the industrial development to occupy a certain share of the market. With the strong support of national policies and the rapid development of technology, the product performance of some domestic enterprises has reached the level of DOE (2015) performance indicators.

At this stage, my country’s graphite bipolar plates can be domestically produced and are relatively mature in terms of technology and commercialization. However, compared with most foreign manufacturers who can directly adopt the production method of die-casting or expanded graphite molding, domestic manufacturers Most of them are realized by artificial graphite machining, and the production technology needs to be improved. If you continue to use mechanical processing, the cost of graphite bipolar plates is really difficult to reduce, and it is difficult to achieve mass production.

After realizing the technology upgrade, mass production can be realized, and the cost will be reduced. In addition, graphite materials can be optimized to develop carbon-based materials with better performance, lower cost, and compression molding. The focus of future research will be on the development of low-cost graphite bipolar plate manufacturing methods.