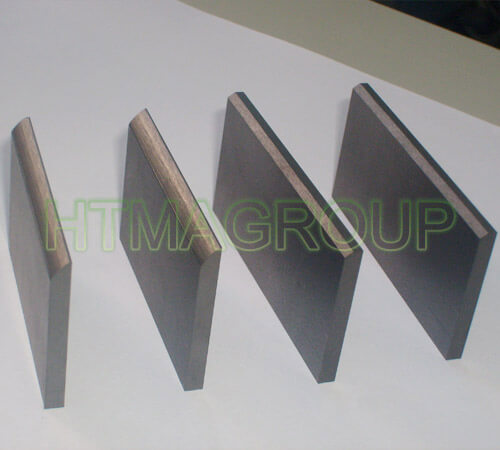

1 vacuum pump blades

Vacuum pump vane, also known as vacuum pump rotary vane, normally the rotary vane vacuum pump are installed inside the vacuum blade, vacuum pump is one of the accessories, when access to the source of the vacuum . Vacuum pump rotary vane in the pump body will not produce friction during operation, and is very easy to cause the vacuum pump blade wear or fracture, swelling and so on in the absence of vacuum pump oil lubrication. Thus leading to insufficient vacuum, the vacuum does not go.

2 application;

Vacuum pump blade is widely used in the rotary vane vacuum pump rotor slot, vacuum pump rotor and the blade are sealed in the vacuum pump cylinder internal use of vacuum pump oil as the lubrication medium to increase the vacuum pump blade and cylinder contact area under the action to achieve the ideal state Ultimate vacuum. If the vacuum pump blade is too short or too thin, will lead to vacuum or even lead to a serious vacuum pump failure.So, It is best to find some professional manufacturers to provide such products!

According to the working principle, the vacuum pump blade is divided into two-stage pump (also known as: bipolar rotary vane vacuum pump) vane and single-stage rotary vane vacuum pump two. Two-stage pump blades in the domestic market for most of the products for the French Leybold, the British Edward brand majority, the domestic brands have 2X series models, mostly. Its different models, different brands, vacuum pump blade size and material are not the same.

3. raw material

In the market, there are a variety of vacuum pump blade material, generally graphite carbon sheet (carbon vane), resin vanes, glass fiber vane, carbon fiber vane, aluminum and other materials. But due to the use of different brands in different models of vacuum pumps, the materials are different.

Graphite vane has the main advantages: the price is relatively low, environmental protection, low noise, small friction on the pump. The disadvantage is easy to break, do not wear.

The main advantages of aluminum: wear, but the price is relatively high, noisy, large friction on the pump.

4. skills requirement

The material of the vacuum pump blade has high bending strength, it is not easy to deform and bend at the time of disturbance and high inlet pressure. The density is smaller than iron, so the centrifugal force is small, not easy to stick with Metal; can withstand high temperature; the coefficient of thermal expansion is small in the length side, and cast iron equivalent, so the design of the direction of tolerance in this direction can be considered cast iron, the expansion coefficient of the thickness side is larger, with higher hardness, oil lubrication friction factor Smaller, in a full oil lubrication condition, with good performance of wear and durable.

We are manufacturer of graphite material and products in china, with stable and reliable quality. Our material: Mouled graphite, isostaitc graphite, vibration graphite, extruded graphite, mechanical graphite and carbon brush materials. Products: machined graphite parts, graphite pipes, mechanical seal and bearing, carbon brushes and graphite bipolar plate..

mechanical carbon vane