Classification of graphite tubes

Graphite tube is divided into two kinds: one is machined graphite tubes from graphite materials, which is pure graphite tube. Another kind is resin graphite tube, using resin and graphite powder kneading, molding, pressing and graphitization.

1) the purity of pure graphite tube is relatively high purity, his purity depends on the raw materials. Materials are mainly molded graphite, isostatic graphite and vibration graphite. The diameter and length of the graphite tube also depended on the size of the raw material.

This kind of graphite tube is mainly used in high temperature industrial field. Products’ size with no restrictions, only depends on the size of raw materials. Large raw materials can be processed to large-size graphite tube, small size of the raw materials can only be processed small graphite tube. But the length of the graphite tube has restrictions of raw material , can only be up to 2 meters.

Application:

Graphite tube / Pipe has a wide range of applications, such as:

1. used for furnace because of graphite heat sensitivity low

2. Used for aluminum degassing

3. Used for dilution pipe used in the production of metal manufacturing

4. Other industries including chemical and scientific using graphite tube

Advantage:

1. high capacity machines, large length and small diameter

2. different application, the effect of different graphite materials well

3. Different needs, different treatment, oxidation resistance, impermeability and strengthened

4. The structure of the uniform

5. high mechanical strength, high precision machine

6. Excellent thermal conductivity

7. The electrical conductivity of the appropriate

8. The lowest wettability of molten metal

9. Hard surface and good bending strength

10. Resistance to chemical attack and thermal shock.

2) resin graphite tube, is a mixture of resin and graphite powder, with process of graphitization. Resin is divided into epoxy resin and phenolic resin. Different resins can be used for different applications. Resin graphite tube length can be done to 6-8 meters, but the diameter depends on the machine, can only do 100mm or so. Standard ID/OD diameter of Resin graphite tube: 32 / 22mm, 37 / 25mm, 51 / 38mm, special diameter special processing. Length 1-6 meters.

Resin graphite tubes are mainly used in heat exchangers.

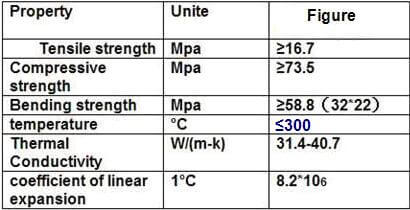

Physical and chemical indicators of resin graphite tube:

Thermal conducting tube Properties:

resin graphite tube data

Graphite sizes:

32/22*2200/3300/4000mm

Unspecified Tolerances:

Dia.s:±0.05mm

Quantity: 350pcs

Penetrability: 10 minutes, under 1Mp pressure, no filter.

The bursting pressure: 6.8Mpa

Resistant graphite tube acid and alkali performance table:

| type | medium | density | temperature /°C | resistance |

| acid | oxalic acid | any | <boiling point | yes |

| aliphatic acid | yes | |||

| acetic anhydride | yes | |||

| oleic acid | yes | |||

| formic acid | yes | |||

| lactic acid | yes | |||

| Citric acid | yes | |||

| tartaric acid | yes | |||

| boric acid | yes | |||

| nitrous acid | yes | |||

| hydrochloric acid | yes | |||

| nitric acid | 5 | room temperature | yes | |

| sulphuric acid | <75 | <120 | yes | |

| sulphuric acid | 80 | <120 | no | |

| phosphoric acid | <80 | <boiling point | yes | |

| hydrofluoric acid | <48 | <boiling point | yes | |

| bromide hydride | 0.5 | 85 | yes | |

| hydrobromic acid | any | <boiling point | no | |

| chromic acid | 10 | room temperature | yes | |

| chromic alkali | 10 | <boiling point | yes | |

| chromic alkali | 40 | room temperature | yes | |

| acetic acid | <50 | <100 | yes | |

| acetic acid | 100 | 20 | yes |

Good reputation, reliable quality, best service and high technologies are our eternal objectives!

Hope we can be your partners soon. We will serve you with our quality products and top technologies and benefit each other.