Graphite bipolar plate has different applications. The most important application is used in fuel cell.

Graphite plate is widely used as bipolar plates for proton exchange membrane fuel cell due to its good electrical conductivity, thermal conductivity and corrosion resistance. But as a result of the graphite plate in the process of burning coal tar as the binder will be oxidized or volatile, cause there are holes with different sizes of graphite plate products, the porosity is about 18% ~ 24%, such a high rate of stomata use graphite plate.

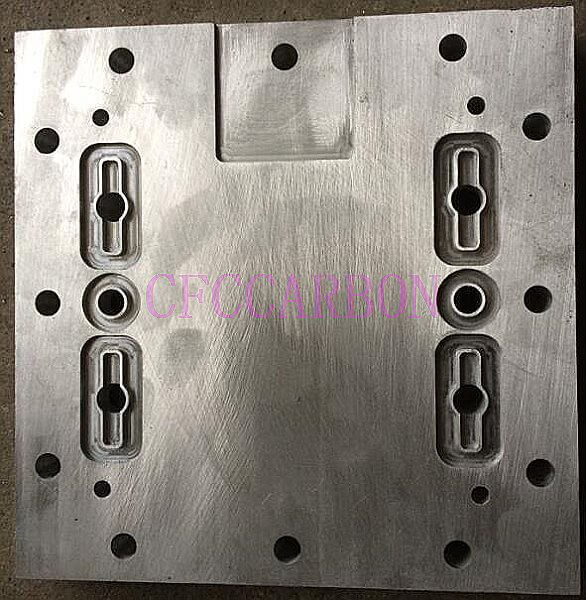

graphite bipolar plate

At present, more and more researchers in the world use organic matter such as phenol formaldehyde resin, paraffin wax, asphalt, carbon silane and other holes to fill the graphite plate, reduce the porosity, to achieve the purpose of sealing graphite plates. Organic matter has the advantages of high molecular weight, long molecular chain and good deformation performance, so it can be well sealed. But because the organic matter seems to penetrate into the graphite plate cavity, and even penetrate into the graphite sheet layer, forming the composite material, thus increasing the resistance and surface resistance of graphite plate. The theory of voltage of single proton exchange membrane fuel cell is only 1.229 V, the greater the material resistance of the battery, the output power is small, therefore, most of the organic material is not suitable for the impregnation of proton exchange membrane fuel cell with graphite bipolar plate.

The performance of the battery stack assembled by the dipping process is much better than the performance of the reactor without impregnation. At the same current density, the average battery voltage is higher than 40 mV, and the open circuit voltage of the battery is increased by more than 20 mV. After impregnation graphite plate used for fuel cell bipolar plates, reaction gas not in series, H2 and O2 in air is not directly in the electric catalyst reaction caused by the loss of water, fuel gas, and beneficial to uniform distribution current in the battery, ensure the battery stack performance.

(1) using graphite bipolar plate in the vacuum pressure immersion Na2SiO3 concentrated solution, and further add acid to heat to make it into the SiO2 method to improve the performance of fuel cell. Under the experimental conditions of keeping the vacuum degree of -0. 1 MPa and the pressure of 0.6 SiO2, the residual amount of in the graphite plate increased with time, and the maximum amount of MPa was up to 7.6%.

(2) the porosity of the graphite plate decreases with the increase of the SiO2 residue, and the porosity of the graphite plate is decreased from 18.2% to 3.3%, and the porosity is reduced by more than 70%. Impregnation process did not affect the resistance of graphite plate.

(3) after impregnation of graphite plate used as a bipolar plate of the proton exchange membrane fuel cell stack, the average voltage of the same current density increased by more than 40 mV, ensuring the performance of the fuel cell.

CFCCARBON LTD has constantly innovated in the research of new bipolar plate , expanded

production capacity and reduced costs, now we become one of the leading manufacturer of bipolar plates in China and have been built long -term relationships with customers all over the world.

Our company can produce graphite bipolar plates for all types. We have the best product lines which can produce wide range of graphite tubes, graphite block, plate for heat exchangers.

We hope to establish a good business relationship with you; we will serve you with the best quality, best delivery time and best solutions