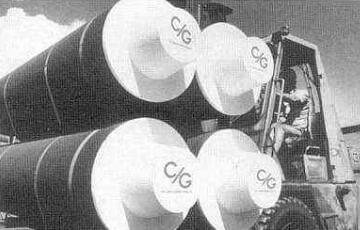

Molded graphite can be defined as a synthetic graphitic product manufactured by a compaction process from a mixture of carbon filler and organic binder which is subsequently carbonized and graphitized. Parts of considerable size, weighing several hundred kilograms, such as the graphite electrodes show in fig.5.1, are

graphite electrodes

manufactured in large quantities.

The basic process was invented by E.G.Acheson, who produced the first molded graphite in 1896. The original applications of molded graphite were electrodes for electric-arc furnaces and movie projectors. Many improvements have been made since then and the applications have increased considerably in scope. Molded graphite is found in almost every corner of the industry world and forms the base of the traditional graphite industry.

It is often difficult to obtain details of a specific process, particularly if such details are not protected by a patent or cannot be revealed by suitable analyses. Most graphite producers claim that such secrecy is necessary because of the high cost of developing new grades of molded graphite, and the need for the new product to remain ahead of competition long enough for the producer to recover his expenses and realize a profit. Fortunately, a great deal of information on the basic materials and processes is disclosed in the open literature.