In this paper, both compressive properties and oxidation behavior of pristine and thermal shock exposed 2D C/C composite specimens were examined. Pristine test specimens were exposed to thermal shock conditions with temperatures ranging from 400C to 1000C in an oxidizing environment, followed by compression tests on pristine and thermal shock exposed specimens to obtain their compressive responses. The experimental results showed that 2D C/C composite compressive stiffness and strength decreased with increasing thermal shock temperature. Also, upon exposure to thermal shock, the stress-strain response displayed a non-linear behavior prior to failure as compared to the pristine C/C composite that failed in a brittle manner. Furthermore, it was observed by microstructural analysis that at low temperatures, i.e., 400C, the oxidation attack was uniform through the interior of the composite. On the other hand, at moderate temperatures, i.e., 600C, oxidation occurred rigorously at the surface of the composite. At high temperatures, i.e., above 600C, the specimens experienced the two aforementioned oxidation mechanisms. Therefore, it was concluded that carbon matrix degraded rapidly when exposed to thermal shock conditions in oxidizing environments and protective coating is required to maintain the quality of the composite under such conditions.

Carbon fiber reinforced carbon matrix composites, called carbon-carbon composites or C/C composites retain exceptional thermal and mechanical properties such as high modulus, high thermal shock resistance and high specific strength at high temperatures in non-oxidizing environments. C/C composites have demonstrated to be very promising candidates to be used as structural components in many defense applications, like navy and aerospace structures. However, most of these components are exposed to thermal shock conditions in oxidizing environments with temperatures above 450C, under which carbon constituents burn away rapidly. Zhao et al. have demonstrated that oxidation has a strong effect on the C/C composite mechanical properties, nevertheless, limited studies have been conducted to analyze the properties and microstructure of unprotected C/C composites under thermal shock conditions in oxidizing environments. Manocha states that when C/C composites are exposed to high temperature tests in oxidizing environments, their properties degrade around 10 to 20% depending on the temperature and time under which they are exposed. Similarly, numerous studies have investigated the tensile and flexural strength of C/C composites at high temperatures, but there is seldom information available about through-thickness compressive properties of 2D C/C composites after being exposed to thermal shock conditions. Therefore, there is a great interest in analyzing the effects of oxidation on the properties and microstructure of C/C composites in order to assure their good performance in high temperature structural applications.

With the increasing thickness of laminates used in naval and aerospace structures, primarily for ballistic applications, understanding the influence of through-thickness and lateral impact loads on the mechanical response and failure has become very critical. Lateral loads often result in delamination type failure due to the presence of weak interfaces. Though these delaminations may not cause catastrophic failure of structures, they jeopardize the structural integrity by reducing their resistance to buckling failure. Therefore, the purpose of this work is to investigate the through-thickness compressive properties of 2D woven C/C composites when exposed to thermal shock conditions in an oxidizing environment.

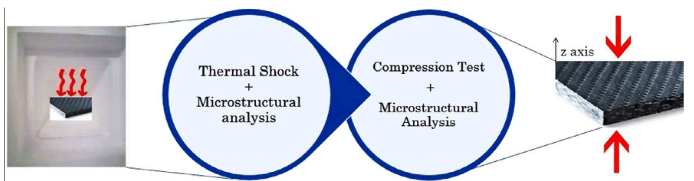

Fig.1-shematc representation of experimental procedure

An overview of the experimental procedure followed in the present study is shown in Fig.1. First, pristine C/C composite specimens were thermally exposed to five different thermal shock condictions, each with peak temperature of 400C, 600C, 700C, 800C and 1000C, respectively. Then, through-thickness compression tests were conducted to determine the compressive stiffness and strength of pristine and exposed C/C composite specimens. Finally, a microstructural analysis of C/C composite specimens exposed to different thermal shock conditions was carried out to analyze the carbon morphology due to oxidation. Similarly, the microstructure of the C/C composite was analyzed after each compression test to identify possible modes of failure.