The size of the particle (grain size), can have a considerable effect on the properties of molded graphite as shown in Table 5.4.

Table 5.4. Effect of particle size on properties

| Grade | Particle

Size Mm |

Density

G/cm3 |

Specific

Resistance O.cm |

Flexural

Strength Mpa |

CTE

M/m.C-10-6 100-600C |

| AI1RL | 0.075 | 1.72 | 0.0016 | 28 | 3.2 |

| AI4RL | 0.025 | 1.82 | 0.0018 | 42 | 5.7 |

| AI5RL | 0.010 | 1.90 | 0.0020 | 77 | 7.0 |

| Notes: CTE=coefficient of thermal expansion | |||||

As shown in the above table, reducing particle size results in an substantial increase in the apparent density and, correspondingly, a lowering of the porosity. The flexural strength is almost tripled. On the negative side, the CTE is more than doubled, which may lead to a decrease in thermal shock resistance. The effect on the electrical resistivity is not as pronounced.

Particle size also affects the finishing since, during maching operations, particles can be torn out of the surface by the tool, leaving a void and the larger the particle, the larger the void. When a smooth finish required with close tolerances, a small particle size material must be selected.

Effect of grain orientation on properties of molded graphite:

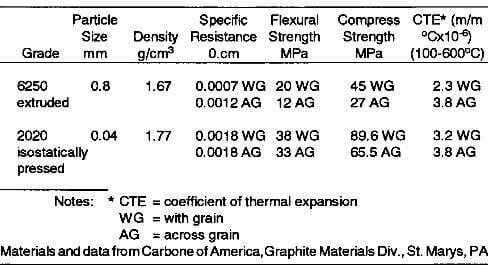

The degree of grain orientation varies with the production process as mentioned above and has a considerable effect on the properties of molded graphite as shown in Table 5.5.

Table 5.5 Effect of grain orientation

effect of grain orientation

The extrusion process tends to align the particles in the extrusion flow direction and extruded graphite has a pronounced anisotropy, particularly in the strength and electrical properties. The isostatic-pressing process, on the other hand, results in a material that is much more uniform and is generally considerably stronger.