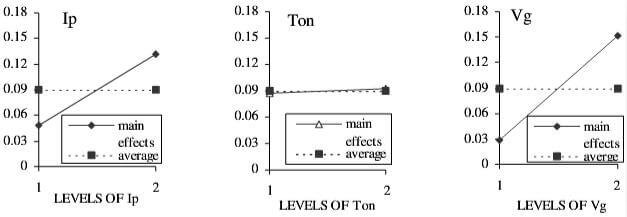

Multiple graphs of main effects and their variation between levels of the parameters on MRR are shown in Fig.2. The relative slope of the linear graphs indicates that Vg is the most significant variable of MRR. It is followed by IP and Ton. Among the parameters Ton is the insignificant one. Since maximum MRR is the requirement the “larger the response the better” is used in the analysis. The overall mean of the main effects is 0.09.

fig.2-Multiple-graphs-showing-main-effects-of-variables-on-MRR

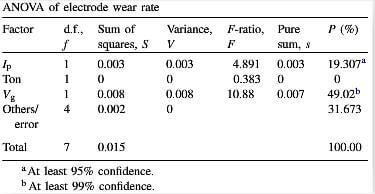

The results of ANOVA for the response function EWR is given in Table 6. Here, the percent contribution indicates that factor Vg contributes the most toward the variation observed on EWR in the experiment followed by Ip and Ton is the insignificant parameter. This agrees to the plots in fig.1. Since the error in only 31.673%, all the major parameters are included and measurement error is not excessive.

table-6-ANOVA-of-electrode-wear-rate

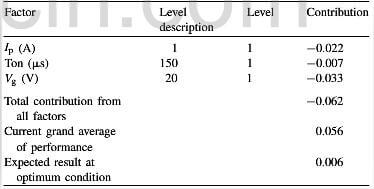

Table 7 gives the optimum conditions of the machining parameters and their levels for EWR. It shows that for optimum electrode wear rate, the levels of the significant variables are their lower levels, i.e., Ip=1A; Vg=20V; and Ton=150μs. It is also expected that this combination of parameters reduce the electrode wear rate from an average value of 0.056-0.006 mg/min. This reduction is attributed to the reduction in energy input rate. The control of electrode wear rate is vital, especially when complex shaped components are finish machined, since it affects the final geometry and dimensions produced.

table-7-Optimum-conditions-and-performance-of-EWR

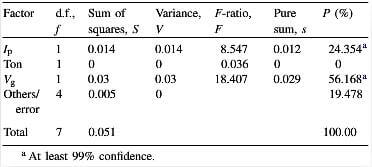

The results of ANOVA for the response function MRR is given in Table 8. COmparison of the percentage contributions of the parameters indicates that Vg is the most significant parameter influencing the MRR followed by Ip and Ton is insignificant. This agrees to the plot in Fig.2. Since the error is only 19.478%, all the major parameters are included and measurement error is not excessive.

table-8-ANOVA-of-MRR