Except ordinary graphite, impregnated graphite, fine particles graphite, high-purity graphite, there is a very special graphite: EDM graphite!

EDM mean Electrical discharge machining, sometimes colloquially also referred to as spark machining, spark eroding, burning,die sinking, wire burning or wire erosion, is a manufacturing process whereby a desired shape is obtained by using electrical discharges (sparks).

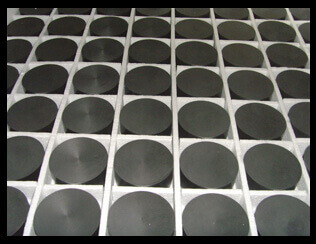

high purity isostatic graphite rods blocks rounds blocks material manufacturer factory China (7)

EDM graphite is mainly used in the production of molds, it has a metal copper can not match the excellent characteristics. EDM graphite itself has the characteristics of non-metallic material at the same time some of the characteristics of metal. EDM graphite is less than metal copper, the quality of light can bring a lot of benefits to the production; easy processing, speaking from the hardness of the electrical spark graphite is one-third of copper metal; and conductivity is less than copper;

The melting point temperature of EDM graphite is higher than copper. copper melting point is about 1,300 degrees, while the EDM graphite melting point is 3800 degrees. High melting point can be greatly reduced after the electronic pulse generated a large number of high-temperature melting itself, resulting in sublimation phenomenon. In addition, EDM graphite processing is simple, fast production, do not worry about capacity problems!

Due to its unique properties, isostatic graphite is the ideal material of choice for conventional sinker EDM applications. Proper material grade selection is one key component of insuring the efficient use of this modern machining technique. A wide range of materials have been developed over the past decade each designed for specific applications. Materials differ in density, strength, hardness and machinability which can affect metal removal rates, electrode wear, surface finishes and dimensional tolerances.

Please see our data sheet /material properties bellow for EDM application:

| Grade | bulk density | grain size | resistance | Thermal conductivity | C.T.E(0-600°C) | hardness shore | Bending strength | Compressive strength | Elastic Modulus | Porosity | Ash content | Purified ash |

| g/cm3 | μm | μΩm | W/m.k | 10-6/°C | HSD | Mpa | Mpa | Gpa | % | ppm | ppm | |

| EDM-5 | 1.68 | 14-15 | 13 | 51 | 38 | 86 | 18 | 500 | 50 | |||

| EDM-6 | 1.78 | 14-15 | 9–10 | 56 | 43 | 85 | 16 | 500 | 50 | |||

| EDM-7 | 1.85 | 8 | 12 | 110 | 3.8 | 67 | 50 | 110 | 11 | 12 | 500 | 50 |

| EDM-8 | 1.86 | 4–6 | 14 | 105 | 4 | 72 | 55 | 120 | 12 | 12 | 500 | 50 |

| EDM-9 | 1.9 | 2 | 14 | 110 | 3.9 | 75 | 60 | 125 | 12 | 10 | 500 | 50 |

We have Chinese graphite materials, and overseas graphite materials from Japan, France, USA. We specialize in precise graphite machining. We are capable of machining different types of graphite, such as graphite rods, graphite blocks, graphite boats, graphite pipes, graphite plates, graphite bearing, graphite heating elements, Vacuum heating furnace, Silicon thermal field, graphite crucibles and other parts from a wide range of applications.

Good reputation, reliable quality, best service and high technologies are our eternal objectives!

Hope we can be your partners soon. We will serve you with our quality products and top technologies and benefit each other.

related news /articles:

CNC machining graphite parts

One of the main application of isostatic graphite: EDM

Big promotion for isostatic graphite rods, size D100-400mm