The deposition of carbon on the filament substructures is accomplished either by pyrolyzing an organic matrix or through CVD. The CVD of carbon from a hydrocarbon gas within a substrate is a complex process. Various

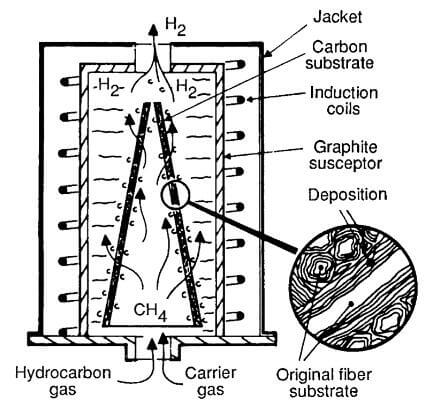

isothermal CVD to infiltrate fibrous carbon substrate

techniques have been applied to infiltrate various fiber substrates including isothermal thermal gradient, pressure gradient, and pressure pulsation. The first two have been the most extensively used. The isothermal technique is illustrated in figure 8. The substrate is radiantly heated by an inductively heated susceptor so that the gas and substrate are maintained at a uniform temperature. Infiltration is normally accomplished at 1100C and at reduced pressures with the flow rates primarily determined by the substrate surface area. This technique produces a crust on the outer surfaces of the substrate, thus requiring machining and multiple infiltration cycles.

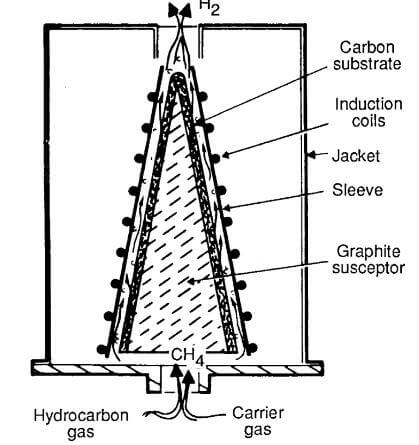

In the thermal gradient technique, the part to be infiltrated is supported by a mandrel that is inductively heated. Therefore, the hottest portion of the substrate is the inside surface, which is in direct contact with the mandrel. The outer surface of the low-density substrate is exposed to a cooler environment and results in a temperature gradient through the substrate thickness. Surface crusting is eliminated because the deposition rate is greater on the heated fibers near the

thermal gradient CVD

mandrel, whereas the cooler outer fibers receive little or no deposit. Under proper infiltration conditions, the carbon is first deposited on the inside surface and, in a continuous process, progresses radially through the substrate as the densified substrate itself becomes inductively heated. Infiltration is normally accomplished at atmospheric pressure with a mandrel heated to about 1100C.