Carbon brush material, also called electric brush material, can be used for generators or electric motors; electrical machinery and carbon brushes. Carbon brush material is a kind of graphite materials we produce.

There are mainly 5types of carbon brush materials, Main types:

1). Metal graphite material.

2). Silver graphite material

3). Pure graphite

4). Resin graphite material

5). Electric graphite material

See the full data sheet of all the grades carbon brushes/electric bruses material bellow:

| Data sheet for carbon brush material –generators or electric motors; electrical machinery; |

||||||||||

| Types | Items | resistivity (μΩ·m) | Short-circuit commutator test | Operating conditions | Main application | |||||

| Voltage drop for a pair brushes (V) | Coef of Friction (≤) | Wear volume for 50hrs (mm) | rating Current density (A/cm2) | Allowable rim speed(m/s) | Pressure issue (kpa) | |||||

| Metal graphite | J102 | 0.115~0.345 | 47~99(392) | 0.30~0.70 | 0.2 | 0.4 | 20 | 20 | 17.6~22.5 | d.c. generators with low voltage and slip rings of a.c. asynchronous motors |

| J105 | 0.03~0.09 | 59~105(392) | ≤0.40 | 0.25 | 0.8 | 20 | 20 | 17.6~22.5 | contacts | |

| C42 | 0.05~0.12 | 30~90(392) | 0.18~0.39 | 0.2 | 0.6 | 20 | 20 | 17.6~22.5 | ||

| C412 | 0.16~0.26 | 50~100(392) | 0.30~0.70 | 0.2 | 0.4 | 20 | 20 | 17.6~22.5 | Slips of current-collectors | |

| J108 | 0.1~0.3 | 47~104(392) | 0.28~0.66 | 0.2 | 0.4 | 20 | 20 | 17.6~22.5 | d.c. generators with low voltage and slip rings of a.c. asynchronous motors | |

| J164 | 0.045~0.135 | 30~92(392) | 0.18~0.42 | 0.2 | 0.7 | 20 | 20 | 17.6~22.5 | d.c. generators with low voltage and slip rings of a.c. commutator machines | |

| J201 | 1.4~5.6 | 64~103(588) | 0.83~2.18 | 0.25 | 0.18 | 15 | 25 | 14.7~19.6 | d.c. generators up to 60V and d.c. welding machines, etc. | |

| H5 | 1.0~4.5 | 65~95(588) | 0.72~1.68 | 0.22 | 0.16 | 15 | 25 | 19.6~24.5 | Slip rings of synchonorous generators, wind driven generators | |

| H71 | 0.25~0.75 | 70~105(588) | 0.50~1.31 | 0.2 | 0.25 | 15 | 25 | 19.6~24.5 | ||

| J203 | 4.4~13.2 | 30~90(588) | 1.17~2.43 | 0.25 | 0.15 | 12 | 20 | 14.7~19.6 | d.c. generators upto 60V | |

| J204 | 0.24~0.96 | 73~105(588) | 0.61~1.60 | 0.2 | 0.3 | 15 | 20 | 19.6~24.5 | d.c.generators up to 80V; small traction morors and slip rings of asynchronous motors. | |

| J245 | 0.23~0.68 | 67~104(588) | 0.36~0.95 | 0.2 | 0.3 | 15 | 25 | 19.6~24.5 | d.c.generators up to 40V; automobiles starters and exciting slip rings of synchronous machines | |

| J205 | 2.4~9.6 | 43~104(588) | ≤2.00 | 0.25 | 0.5 | 15 | 35 | 14.7~19.6 | Density: 3.75-4.56 | |

| J206 | 2.0~6.0 | 65~104(588) | 0.97~2.03 | 0.2 | 0.3 | 15 | 25 | 14.7~19.6 | 19.6~24.5 | |

| J210 | 0.22~0.88 | 40~96(588) | 0.61~1.60 | 0.25 | 0.3 | 15 | 25 | 14.7~19.6 | d.c.generators upto 60V; automobile starting motors and slip rings of asynchronous motors. | |

| J213 | 0.22~0.88 | 67~104(588) | 0.39~1.02 | 0.2 | 0.4 | 15 | 20 | 19.6~24.5 | ||

| J215 | 2.0~6.0 | 65~105(588) | 0.96~2.24 | 0.25 | 0.14 | 15 | 20 | 20~25 | ||

| J230 | 0.6~1.8 | 70~105(588) | 0.50~1.20 | 0.2 | 0.25 | 15 | 35 | 14.7~19.6 | Automobile starters and exciting slip rings of synchronous machines | |

| J240 | 1.0~4.0 | 66~113(588) | 0.78~1.82 | 0.25 | 0.2 | 15 | 35 | 19.6~24.5 | ||

| J241 | 1.17~4.03 | 60~100(588) | 0.70~1.70 | 0.25 | 0.3 | 15 | 35 | 14.7~19.6 | ||

| Silver graphite | J239 | 1.05~3.15 | 47~99(392) | 0.05~1.62 | 0.2 | 0.25 | 15 | 35 | 14.7~19.6 | |

| J412 | 0.35~1.05 | 30~93(392) | 0.42~1.24 | 0.2 | 0.3 | 15 | 25 | 19.6~24.5 | ||

| J453 | 0.72~2.88 | 64~103(588) | 0.60~1.42 | 0.2 | 0.3 | 15 | 35 | 19.6~24.5 | Generators for car window scraper, warm air motors, motorcycles. | |

| J390-1 | ≤0.15 | 48~112(588) | ≤0.30 | 0.25 | 0.5 | 20 | 15 | 14.7~19.6 | ||

| J390 | 0.03~0.1 | 30~90(588) | <0.20 | 0.25 | 9 | 20 | 15 | 14.7~19.6 | ||

| J385 | 0.04~0.13 | 47~102(392) | 0.05~0.30 | 0.25 | 6 | 20 | 15 | 14.7~19.6 | Slip contacts for conducting current and transmit signal | |

| J385-3 | 0.04~0.20 | 50~104(588) | ≤0.40 | 0.25 | 5 | 20 | 15 | 14.7~19.6 | Contacts for signal devices; a.c. miniature electrical machines. | |

| J380 | 0.08~0.24 | 47~95(392) | 0.12~0.50 | 0.25 | 4 | 20 | 15 | 14.7~19.6 | ||

| J375 | 0.1~0.4 | 50~104(588) | 0.14~1.00 | 0.28 | 3 | 15 | 20 | 14.7~19.6 | ||

| J370 | 0.12~0.70 | 30~100(588) | 0.25~1.20 | 0.28 | 2 | 15 | 20 | 14.7~19.6 | ||

| J360 | 0.3~1.2 | 50~104(588) | 0.40~1.50 | 0.28 | 1.8 | 15 | 20 | 14.7~19.6 | ||

| J350 | 0.8~4.0 | 30~104(588) | 0.60~1.80 | 0.3 | 0.8 | 15 | 20 | 14.7~19.6 | ||

| J325 | 5.0~12.0 | 30~100(588) | 0.80~2.00 | 0.25 | 0.4 | 15 | 20 | 14.7~19.6 | ||

| Pure graphite | S3 | 9~17 | 30~94(588) | 1.58~2.63 | 0.25 | 0.2 | 11 | 25 | 19.6~24.5 | |

| S6 | 14~26 | 47~95(196) | 1.35~2.25 | 0.33 | 0.2 | 12 | 70 | 14.7~19.6 | ||

| S6M | 13~23 | 82~112(196) | 1.19~2.21 | 0.33 | 0.15 | 10 | 70 | 14.7~19.6 | 80-120 V d.c machines | |

| S7 | 17~25 | 46~77(196) | ≤2.50(single) | 0.27 | 1.50(100h) | 10 | 70 | 14.7~19.6 | Steel Slip rings for high speed steam turbo-generators | |

| Resin graphite | S-28 | 98~182 | 74~121(196) | 3.20~4.80 | 0.25 | 0.25 | 10 | 35 | 19.6~31.4 | |

| S4 | 80~150 | 85~125(196) | 3.50~5.00 | 0.2 | 0.15 | 8 | 35 | 19.6~31.4 | Especially suitable for slip rings of large turbo-generators | |

| S31 | 770~1430 | 44~73(588) | 6.32~9.48 | 0.25 | 0.2 | 10 | 30 | 20~35 | Electric tools motors | |

| RO15 | 329~611 | 76~120(196) | 3.36~6.24 | 0.2 | 0.15 | 8 | 30 | 19.6~31.4 | ||

| R211 | 147~273 | 56~84(588) | 3.60~5.40 | 0.2 | 0.15 | 8 | 35 | 24.5~34.5 | Highspeed series motors | |

| R608 | 156~634 | 75~123(196) | 3.40~5.20 | 0.2 | 0.2 | 8 | 35 | 24.5~34.5 | Electric tools, household applicances | |

| Electric graphite | D104 | 6~14 | 71~110(196) | 1.92~2.88 | 0.2 | 0.25 | 12 | 40 | 14.7~19.6 | d.c. or a.c. commutator machines |

| D172 | 7.8~18.2 | 71~112(196) | 2.16~3.24 | 0.25 | 0.2 | 12 | 70 | 14.7~19.6 | Electric tools, electric motors, radio jamming resistance | |

| D172NM | 9~21 | 71~112(196) | 1.68~2.52 | 0.2 | 0.2 | 12 | 70 | 14.7~19.6 | d.c. welding dynamous and 80-120V d.c. machines | |

| D213 | 22~36 | 55~103(980) | 1.95~3.25 | 0.25 | 0.15 | 10 | 40 | 19.6~39.2 | Highspeed turbo-generators and d.c. machines of small /medium size | |

| D214 | 21~35 | 55~103(980) | 1.80~3.00 | 0.25 | 0.15 | 10 | 40 | 19.6~39.2 | Especially suitable for slip rings of large a.c. motors | |

| D252 | 10.5~19.5 | 50~98(588) | 1.88~3.13 | 0.25 | 0.15 | 12 | 45 | 19.6~24.5 | Automobile generators and traction motors with mechanical vibration | |

| D308L | 30~56 | 70~105(980) | 1.95~4.05 | 0.25 | 0.15 | 10 | 40 | 19.6~39.2 | Exciters of turbo-generators; d.c. machines with shock load | |

| D3O8 | 28~52 | 47~108(980) | 1.69~3.51 | 0.25 | 0.15 | 10 | 40 | 19.6~39.2 | 120-140V d.c. machines, automobile generators and traction motors | |

| D312 | 25~46 | 61~101(980) | 1.62~3.38 | 0.25 | 0.1 | 12 | 50 | 19.6~39.2 | d.c. motors with difficulties of commutation, highspeed d.c. motors, micro d.c. motors and motors for electric toods. | |

| D374L | 35~65 | 62~102(980) | 1.89~3.92 | 0.2 | 0.12 | 12 | 50 | 19.6~39.2 | Amplidynes and small d.c. machines with high angular velocity | |

| D374F | 40~74 | 58~108(980) | 1.75~3.65 | 0.2 | 0.2 | 12 | 50 | 19.6~39.2 | ||

| D374B | 40~74 | 54~100(980) | 1.82~3.78 | 0.25 | 0.25 | 12 | 50 | 19.6~39.2 | Small high speed series motors | |

| D374N | 41~75 | 54~100(980) | 1.82~3.78 | 0.2 | 0.2 | 12 | 60 | 19.6~39.2 | Traction motors and d.c. machines for difficulty in commutation | |

| D374S | 40~74 | 54~100(980) | 1.82~3.78 | 0.2 | 0.2 | 12 | 50 | 19.6~39.2 | Traction motors and main generators for locomotives high speed excites for turbo-generators, rolling mill motors, and main generators, e.c. commutator motors and other d.c. motors with some difficulties of communtation | |

| D376 | 42~78 | 82~116(588) | 1.89~3.92 | 0.25 | 0.25 | 12 | 50 | 19.6~39.2 | ||

| D376N | 43~81 | 82~116(588) | 1.89~3.92 | 0.2 | 0.2 | 12 | 60 | 19.6~39.2 | ||

| D376Y | 43~81 | 82~116(588) | 1.89~3.92 | 0.2 | 0.2 | 12 | 50 | 19.6~39.2 | ||

| Note:“( )”:Load,Unit:newton (N) | ||||||||||

| Standard sizes for raw material: Metal+graphite:(21-41)*108*126mm; (21-41)*120*138mm; (21-41)*68*148mm Silver+graphite: (20-40)*32*60mm ; (20-40)*65*82mm; (20-40)* 68*148mm Electric graphite:(21-41)*108*126mm Resin+graphite:(21-36)*67*135mm———————————— CFCCARBON/ HTMAGROUP Email: potter@cfccarbon.com hiclsun@gmail.com Sales manager: +86-18910941489 Humen Resource: +86-15313026852 Carbon, Graphite, Carbon composite! |

||||||||||

Donwload the full file at: https://www.cfccarbon.com/wp-content/uploads/2017/11/Data-sheet-carbon-brush-material.xls

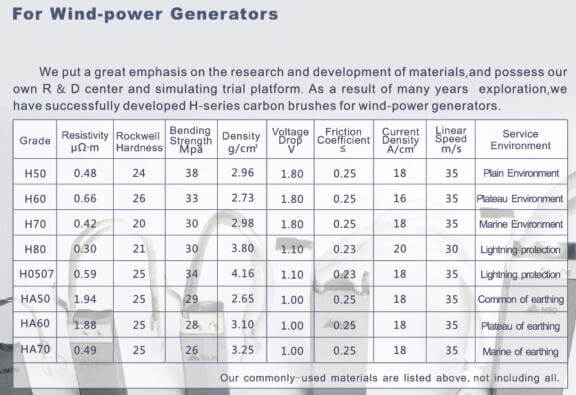

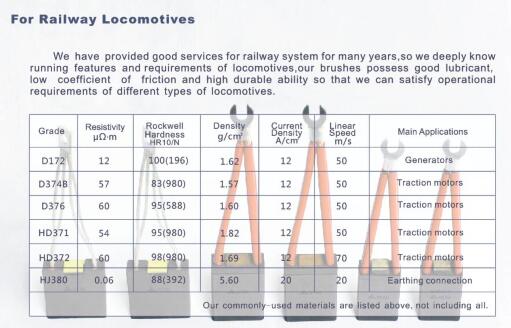

Applications of carbon brush/electric brush: Our carbon brushes are used in wind power generators, big ship engines and other big machines; Our carbon brushes are used in steel processing, mining, wind power generators, traction and a wide range of general industrial applications all over the world. We hope to establish a good business relationship with you; we will serve you with the best quality, best delivery time and best solutions. see bellow special grades for special applications: wind power/energy generators and traction motors:

carbon brush material data sheet-grades for wind power generators

data sheet of carbon brush materials for railway locomotives-traction motors

We hope to establish a good business relationship with you; we will serve you with the best quality, best delivery time and best solutions