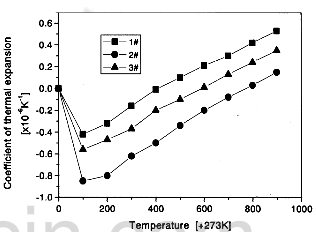

The effect of preform architectures on the CTE for the C/C composites 1#, 2#, and 3#, is shown on Fig.3. The three composites all have very small CTE with values from -0.85 ×10-6/K to 0.66 ×10-6/K in the range 0-900C. Compared with the CTE vs. T curve of graphite, their slope of the curves is smaller, which is probably owing to the restriction of the interfaces between CF and PyC when expansion or shrinkage occurs. In the same temperature range they present negative expansion behaviors. The negative expansion effect is the most obvious in the range 0-100C, but above 0-100C, their CTE variation with temperature is approximately linear and the slope of CTE vs. T curves is the same roughly. Composite 1# has the highest negative and positive CTE, that of composite 2# is the lowest, and that of composite 3# is the between that of them.

effect of the preform architectures on CTE of e CC composites

The CTE of C/C composites abides by the mixture regulation,

αc=νf·αcf+νm·αcm, (1)

where Vf and Vm denote the volume fraction of the CF and PyC respectively, αf andαm stand for the CTE of the CF and PyC respectively. The value of exponent c is about equal to 1. So the above expression becomes

α=νf·αf+νm·αm, (2)

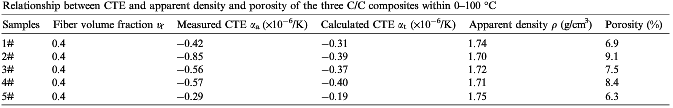

the CTE of PAN-based CF is about 1 ×10-6/K in the axis direction. For the five composites, a comparison between the calculated and measured CTE values in the range 0-100C is listed in Table 1. From table 1, their absolute calculated values are smaller than those of the measured negative expansion owing to the important contribution of the pores in the C/C composites, and under the present conditions, the values of CTE are inversely proportional to their porosity. The fewer the pores of the C/C composites are, the larger their CTE are usually, which agrees with the conclusion drawn by Baxter et al.

relationship between CTE and density of CC composite

When the C/C composites is heated in a condition of lower temperature, the volatilization of the absorbed water in them make the pores shrink, and the more porosity allows the composites to absorb more water, which results in more shrinkage. The five composites possess different porosity, which explains their differences of the largest negative CTE. Composite 2# possesses the highest porosity, and its preform consists of the discontinuous short fibers distributed disorderly and directed at random, so the contribution of the CF on the CTE is very small. Also, the matrix carbon is encircled closely on the surface of the CF, which produces the intensive restriction for the CF expansion with the temperature. In consequence, under the same temperature range, composites prepared using chopped fibers show the least CTE. For composite 1# with low porosity, the continuous long fibers exist in the X-Y direction, therefore their CTE is the highest, and they possess the smaller absolute value of the negative CTE owing to lower porosity under the same conditions. But the fibers of the carbon clothes are twined together with in the X-Y direction, the expansion of the fibers is also restricted, which leads to the CTE of composite 3# is smaller than that of composite 1#, but larger than that of composite 2# in the same conditions.