Low-expansion structures: The low thermal expansion of C/SiC fibre ceramics in combination with their high rigidity and stability is utilized in low-expansion structures. Not the high-temperature properties are relevant for this application, but rather the options to produce large-sized components with high precision as well as the material properties that are not influenced by ambient conditions.

Calibrating bodies used in industrial measurement technology are a very interesting application for C/C-SiC composites. Among others,

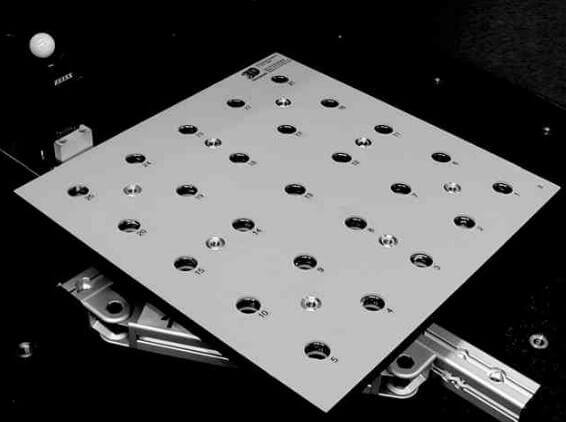

fig.6-CC-SiC calibrating plate with 25 holes for the calibration machines

plate-shaped calibraing bodies are used to check coordinate measuring machines, in order to be able to recognize inaccuracies in measuring legnths and angular displacements of the automatic measuring systems in the automotive industry, for example. These high-precision components must have a very low and a constant thermal expansion coefficient iwthin the normal temperature range of -30 to +50°C. In addition, the calibrating plates should be simple to handle, i.e. light-weighted and robust. This requirement profile is impressively fulfilled by C/C-SiC composites. Figure 6 shows such a calibrating plate with an edge length of 420 mm and a thickness of 8 mm with 25 measurement bore holes.

The advantages of C/C-SiC composites compared to conventinal low-expansion materials are the absence of any kind of thermal hysteresis, a low heat capacity, a considerably lower weight in combination with a sufficient damage tolerance of the component.

Advantages for the customer arise here from primarily in mobile use, where the handling of the plates has been made fundamentally easier, and the waiting times for temperature equalization between the calibrating plate and the measuring room has been reduced.

Satellite communication systems based on optical concepts enable high data rates with a relatively low energy consumption compared

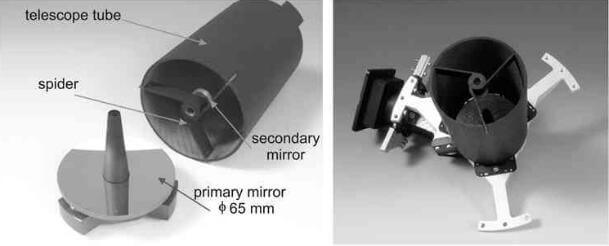

fig.7-Optical unit for laser communication satellite consisting of low expansion CC-SiC tube and spider

to systems based on radio waves. However, an optical system has high demands on precision and stability. In this application the demands on thermal and structural stability are extreme. Novel C/C-SiC composites have been designed under the aspect of series manufacture especially for this purpose. Fig.7 shows the optical unit consiting of a primary and secondary mirror, connected with a telescope tube and spider element of low expansion C/C-SiC. In the final assembly the tube is aligned with the mirror optical axis in vertical direction. The secondary mirror faces the primary and the protruding rectangular blades of the tube are connected to the mirror cell by adhesive bonding.

The given telescope tube and spider element design with C/C-SiC composites enables integral manufacture in comparision to conventional non-CMC solution where parts must be glued together. In addition, the design exhibits no hygroscopicity, demonstrates fracture toughness and is lightweight.

To continue…

Related news /knowledge:

- Carbon fiber reinforced silicon carbide composites (C/SiC, C/C-SiC)-(3)-application

- Carbon fiber reinforced silicon carbide composites (C/SiC, C/C-SiC)-(5)-application

- Carbon fiber reinforced silicon carbide composites (C/SiC, C/C-SiC)-(6)-processing

- Carbon fiber reinforced silicon carbide composites (C/SiC, C/C-SiC)-(7)-processing