Carbon Fiber Composite (CFC) and Ceramic Matrix Composite (CMC) are two of the most advanced materials used in engineering and manufacturing today. Both materials have unique properties that make them ideal for a variety of applications. In this article, we will explore the properties, applications, and advantages of each material.

Carbon Fiber Composite (CFC):

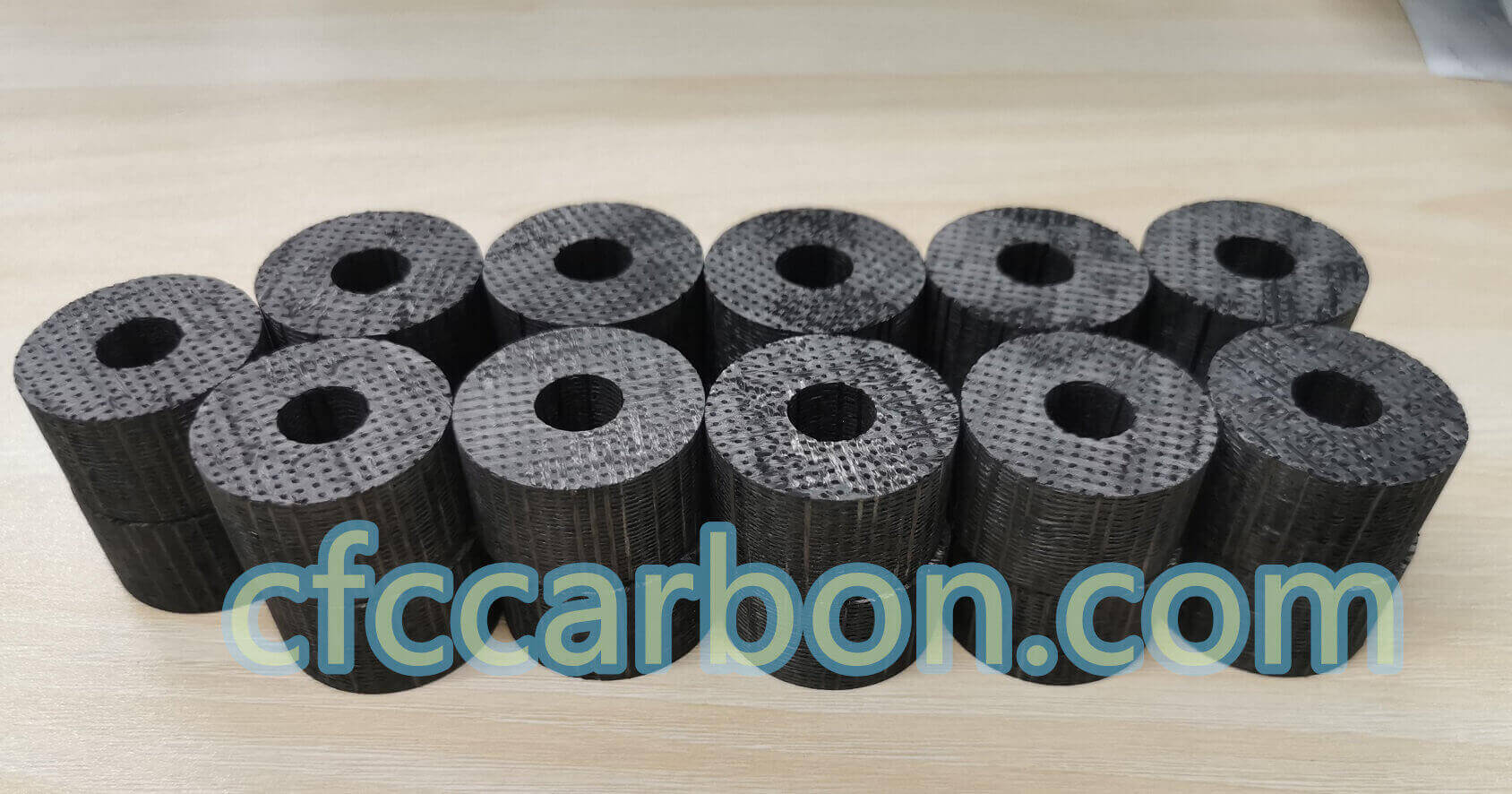

carbon fiber composite pipe-tube-3D structure-CFC-CC

Carbon Fiber Composite (CFC) is a material made from carbon fiber and resin. The carbon fibers are woven together to create a strong, lightweight structure, which is then infused with resin to hold the fibers together. The resulting material is extremely strong and lightweight, with a high strength-to-weight ratio.

Properties of Carbon Fiber Composite (CFC):

The unique properties of CFC include its high strength, low weight, and resistance to heat, chemicals, and corrosion. CFC is also non-magnetic and non-conductive, making it ideal for use in sensitive electronic equipment.

Applications of Carbon Fiber Composite (CFC):

CFC is commonly used in aerospace and aviation, as well as in the automotive and sports industries. It is used to create parts such as aircraft wings, car body panels, and sporting equipment such as tennis rackets and bicycles. CFC is also used in the construction of buildings and bridges, as it is strong enough to support heavy loads while remaining lightweight.

Advantages of Carbon Fiber Composite (CFC):

The main advantage of CFC is its high strength-to-weight ratio. This makes it ideal for applications where strength and durability are important, but weight is a concern. CFC is also resistant to heat, chemicals, and corrosion, which makes it a durable material that can withstand harsh environments.

Ceramic Matrix Composite (CMC):

SiCf-SiC pipes (2)

Ceramic Matrix Composite (CMC) is a material made from ceramic fibers and a ceramic matrix. The ceramic fibers are woven together to create a strong, lightweight structure, which is then infused with a ceramic matrix to hold the fibers together. The resulting material is extremely strong and lightweight, with a high strength-to-weight ratio.

Properties Ceramic Matrix Composite (CMC):

The unique properties of CMC include its high strength, low weight, and resistance to heat, chemicals, and corrosion. CMC is also non-magnetic and non-conductive, making it ideal for use in sensitive electronic equipment. Additionally, CMC is able to withstand extremely high temperatures, making it ideal for use in high-temperature applications.

Applications Ceramic Matrix Composite (CMC):

CMC is commonly used in aerospace and aviation, as well as in the automotive and energy industries. It is used to create parts such as aircraft engine components, gas turbine blades, and automotive brake disks. CMC is also used in the construction of buildings and bridges, as it is strong enough to support heavy loads while remaining lightweight.

Advantages Ceramic Matrix Composite (CMC):

The main advantage of CMC is its ability to withstand extremely high temperatures. This makes it ideal for use in high-temperature applications, such as in gas turbines and aircraft engines. CMC is also resistant to heat, chemicals, and corrosion, which makes it a durable material that can withstand harsh environments.

Conclusion:

In conclusion, both Carbon Fiber Composite (CFC) and Ceramic Matrix Composite (CMC) are advanced materials that have unique properties and advantages. CFC is ideal for applications where strength and durability are important, but weight is a concern. CMC is ideal for high-temperature applications where extreme heat resistance is required. Both materials are widely used in aerospace, aviation, automotive, and energy industries, as well as in the construction of buildings and bridges.

related news /knowledge:

carbon carbon composite, CFC, Carbon composite, C/C

Carbon ceramic composite material and parts

Carbon fiber reinforced silicon carbide composites (C/SiC, C/C-SiC)-(1)

Ceramic matrix composite (CMC) material | professional manufacturer in China