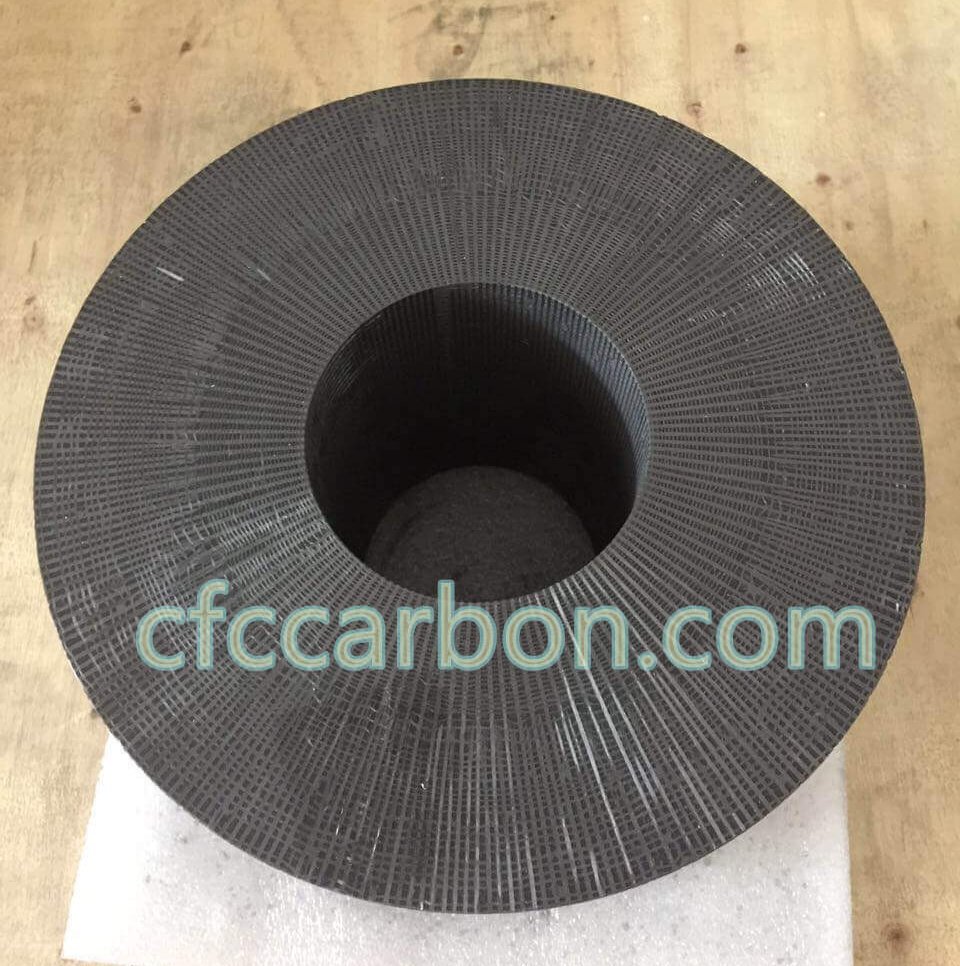

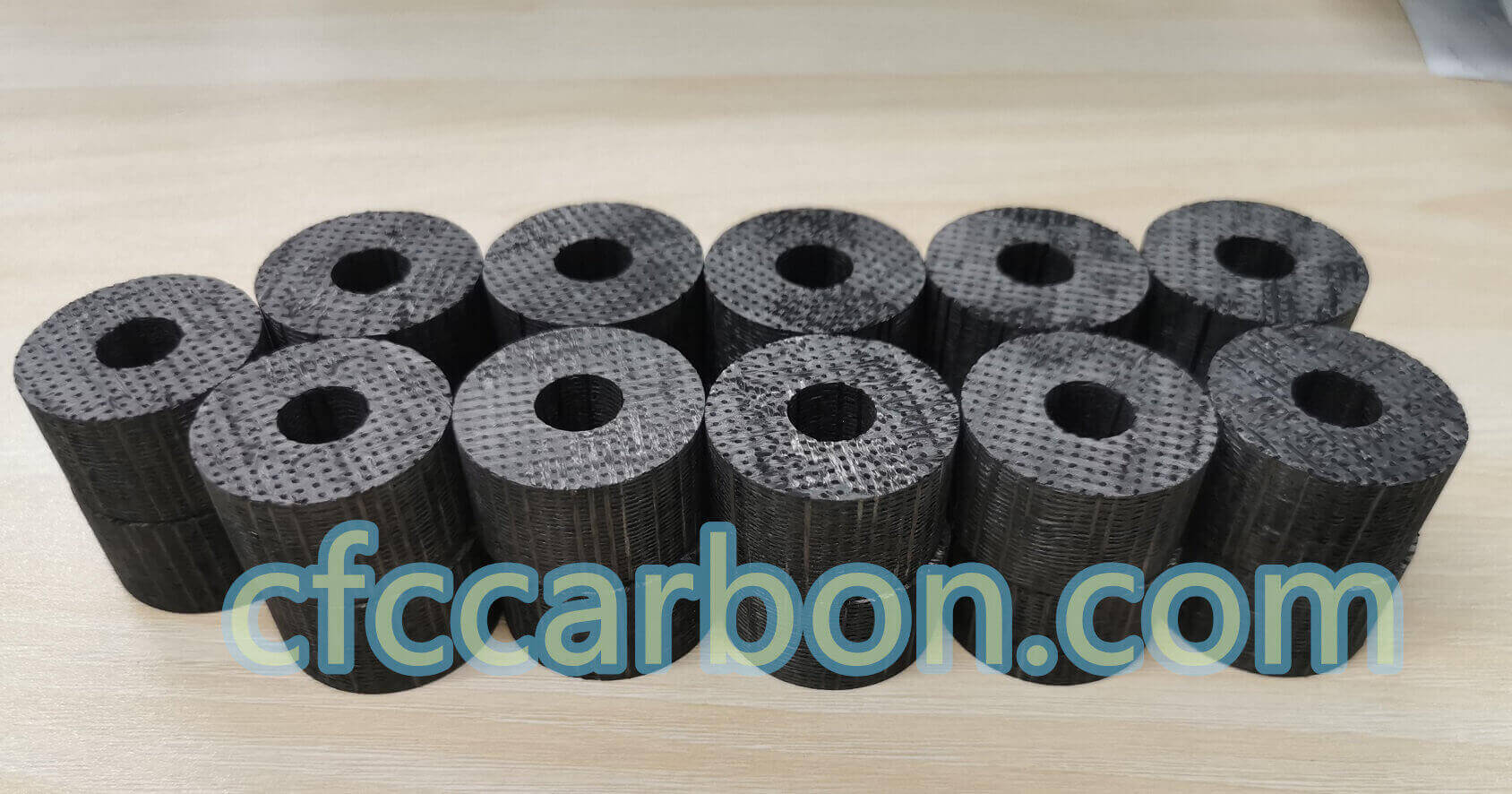

CFCCARBON LTD is a group company, specializing in the production of carbon carbon composite| C/C composite material. We can produce all kinds of 3D C/C composite for different applications. We can produce all types of 3D C/C composite with stable and reliable quality. 3D C/C composite material has the advantages of low competitive costs, long lasting lifetime, more clean…

3D 4D 5D Hoops, Loop, weaving, stucture, drawing, carbon fiber, carbon, composite, CFC, CC, manufacturer, China, (1)

For 3D C/C composite, we can produce with density of 1.4-1.95g/cm3, different structures, others as per customers’ requests. Prices of carbon composite available in other article.

Carbon-carbon composite properties/ features:

(1) Physical properties: After high temperature treatment, the carbon composite has higher carbon content, >99%, the density is low, the mechanical properties are good. Due to good characteristic of high melting point of carbon, high temperature resistance, corrosion resistance and thermal shock performance, the carbon composite is resistant to acid, alkali and salt.

(2) Mechanical properties: carbon composite has good mechanical properties of the strength and elastic modulus, good wear and tear resistance.

(3) high-temperature stability: The room temperature strength of carbon composite can keep up to 2500 ℃, is not sensitive to the thermal stress, and the ablation resistance performance is good.

(4) Comprehensive performance evaluation: carbon composite has good strength and elastic modulus at room temperature; less production processes of carbon composite material can save materials and manufacturing costs, and its more safety and reliability.

Special Properties of carbon carbon composite: High Acid-resisting and alkali-resisting properties; Low density compared to metals; High temperature, cold-resistant, tensile strength is 7-9times than Steel; very good thermal shock resistance…

Due to the characteristics above, Carbon carbon composite (C/C composite ) is widely used in various fields of the national economy:

carbon fiber composite pipe-tube-3D structure-CFC-CC

1, carbon carbon compoiste is first used in the aerospace field. It has developed a secondary structure of the aircraft pieces, such as vertical tail, brake pads, rudder and other carbon fiber composite materials. Carbon fiber composite materials can also be used for missile nose cone, nozzle, solid rocket engine.

2, the amount of sports and leisure goods carbon fiber accounted for 80% of the total. Mainly used in golf clubs, fishing rods, badminton rackets, table tennis rackets, rowing, bicycles and other industries.

3, oxidized fiber, carbon carbon gasket material is used in industrial carbon fiber products, the largest amount of varieties. Mainly used for power plants, chemical plants, fertilizer plants and oil fields such as high pressure, corrosion-resistant pumps and valves. The function and life of these sealing materials is much better than asbestos.

4, in the textile industry, of which 30% to 40% of the looms use carbon carbon rapier head, rapier band. The main advantage is a good wear resistance and conductivity, to ensure that the product geometry stability.

5, in the electronics industry, the use of carbon carbon high conductivity, developed a new JXQ-1, JXQ-2 self-induced static eliminator, but also the use of carbon fiber composite materials developed large motor anti-corona material, to prevent large motor Start the corona spark, reducing the size of the motor has a great significance.

6, in the automotive industry, carbon carbon composite brakes have been used for motor vehicles. Carbon fiber composite is also used in spectacle frames, audio equipment, medical equipment, human medicine, biological engineering, building materials and other fields.