High density carbon carbon composite normally with structure of 3D or 4D, with density higher than 1.80g/cm3. So the applications of high density C/C composite is same as 3D or 4D C/C composite. The applications area are: Heat Treatment; Semiconductor; Photovoltaic; Automotive; Aerospace; Display Manufacturing; Railway and Others. Here we mainly introduce the application on aerospace.

The application high density CC composites:

When Missiles, manned spacecraft, space shuttle, re-entry environment, the head part of the aircraft will bear a strong shock, and under a lot of pressure, the most demanding parts may reach an temperature of up to 2760 ℃, it must choose to right material.that can withstand reentry environment Harsh conditions. The reasonable design of the nose cone shape and selection of material, can make the actual flow of energy into the aircraft only about 1% to 10% of the heat.

The end cap of the missile, also requires anti-heat material in the re-entry environment, Low ignition loss rate, and smooth/even loss in each direction, and hope it has the ability to absorb waves, anti-nuclear radiation performance and use in all weather performance. 3D and 4D C/C composite, its thermal conductivity after graphitization is sufficient to meet the thermal re-entry requirements from -160 ° C to 1700 ° C during pneumatic reheating, which can prevent the overall damage caused by excessive thermal stress of the nose cone of the warhead; and its low density can improve Missile warheads. This have been used in many strategic missile warheads

In addition to the reentry nose cone, C / C composites can also be used as thermal protection materials for the space shuttle

Application on solid rocket engine nozzle:

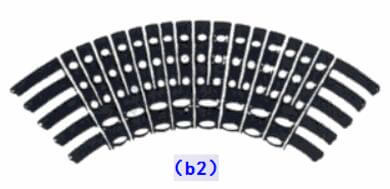

C / C composite material since the last century 70’s for the first time as solid rocket engine (SRM) throat liner flight success, it has greatly promoted the SRM nozzle material development. The use of C / C composite throat lining, expansion, extended outlet cone, with very low ignition loss rate and good ablation profile, can improve the nozzle efficiency of 1% to 3%, can greatly improve the SRM ratio. Generally the throat part use of multidimensional braided high-density Pitch-based C / C composites, reinforcement for the overall acupuncture carbon felt, multi-directional weaving, etc., and the surface coating SiC to improve oxidation resistance and erosion resistance. The application of the United States in this regard are: ① “militia 2 Ⅲ” missile engine, the third stage of the nozzle lining material; ② “Polaris” A27 engine nozzle convergence; ③MX missile third-stage engine can extend the export cone Woven thin-walled C / C composite products). Russia used in submarine missile engine nozzle extension cone (three-dimensional braided thin-walled C / C composite products)

CFCCARBON LTD is a group company, specializing in the production of high density carbon carbon composite, inclusding 3D or 4D C/C composite.

For the carbon carbon composite, there are so many names of this material, different people use different names when refer to the same product. But its same material.

Names of the material: CFC, Carbon composite, C/C, carbon fiber composite, carbon carbon composite, carbon reinforced carbon, carbon fiber reinforced carbon, carbon carbon.

high density Carbon carbon composite properties / features:

(1) Physical properties: After high temperature treatment, the carbon composite has higher carbon content, >99%, the density is low, the mechanical properties are good. Due to good characteristic of high melting point of carbon, high temperature resistance, corrosion resistance and thermal shock performance, the carbon carbon composite is resistant to acid, alkali and salt.

4d-xyz-structure-carbon-carbon-composite

(2) Mechanical properties: carbon carbon composite has good mechanical properties of the strength and elastic modulus, good wear and tear resistance.

(3) high-temperature stability: The room temperature strength of carbon carbon composite can keep up to

2500 ℃, is not sensitive to the thermal stress, and the ablation resistance performance is good.

(4) Comprehensive performance evaluation: carbon carbon composite has good strength and elastic modulus at room temperature; less production processes of carbon carbon composite material can save materials and manufacturing costs, and its more safety and reliability.

4d hoop structure cylinder weave carbon composite

Note: We can do X-RAY tests and other tests.

We can produce with all shapes of 4D C/C as per customers’ special request.

Our Products were sold throughout the country and exported to many countries and regions which enjoy a high reputation all over the world. We hope to establish a good business relationship with you; we will serve you with the best quality, best delivery time and best solutions