Introduction of carbon carbon composite, CFC, Carbon composite, C/C,

introduction of carbon composite. different names: CFC, Carbon composite, C/C, carbon fiber composite, carbon carbon composite, carbon reinforced carbon, carbon fiber reinforced carbon, carbon carbon.

Detailed description

In this article, we will make a brief introduction of carbon carbon composite material, which has so many different names. Different people use different names when refer to the same product, while its same kind of material.

Names of the material: CFC, Carbon composite, C/C, carbon fiber composite, carbon carbon composite, carbon reinforced carbon, carbon fiber reinforced carbon, carbon carbon.

Production process: first, we use carbon fiber, or graphite fiber to make a special shape, then we use the ways of CVI, or CVD, or other way to increase the density. the production takes a long time, about 5-8months due to different size product.

Carbon-carbon composite features:

(1) Physical properties: After high temperature treatment, the carbon composite has higher carbon content, >99%, the density is low, the mechanical properties are good. Due to good characteristic of high melting point of carbon, high temperature resistance, corrosion resistance and thermal shock performance, the carbon composite is resistant to acid, alkali and salt.

(2) Mechanical properties: carbon composite has good mechanical properties of the strength and elastic modulus, good wear and tear resistance.

(3) high-temperature stability: The room temperature strength of carbon composite can keep up to 2500 ℃, is not sensitive to the thermal stress, and the ablation resistance performance is good.

(4) Comprehensive performance evaluation: carbon composite has good strength and elastic modulus at room temperature; less production processes of carbon composite material can save materials and manufacturing costs, and its more safety and reliability.

Special Properties of carbon carbon composite: High Acid-resisting and alkali-resisting properties; Low density compared to metals; High temperature, cold-resistant, tensile strength is 7-9times than Steel; very good thermal shock resistance…

Type of carbon carbon composite:

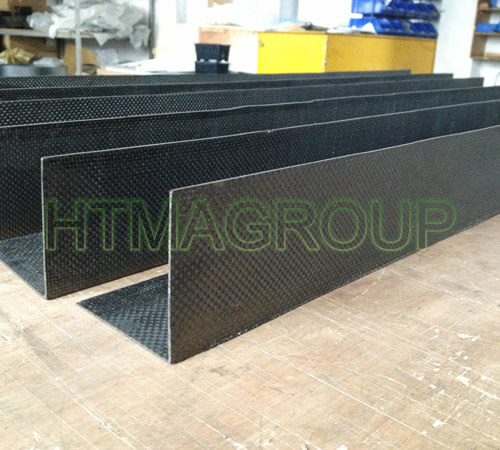

What is 2D carbon carbon composite? Its only 2 directions of the fibers. mainly x, y directions in the plane direction. Most of the time, the product is produced by carbon fiber cloths, stick together layer by layer, such as carbon composite boards, carbon composite sheets, carbon composite U, L profiles for heaters…

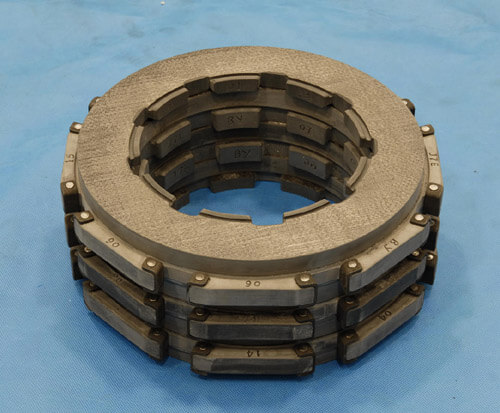

What is the 2.5D carbon carbon composite? Its based on the 2D carbon composite, and has some fibers between the layers of carbon cloths. Its 3directions, but the z direction has less fiber. We call it 2.5D. Our carbon composite airplane brakes are made of this type of material. Its specially designed for airplane brakes. Carbon / carbon composite material is a porous brittle material, afraid of wet, afraid of oil, fear of oxidation, fear of bruising, fear of bruising, fatigue, compared to Steel, Therefore, carbon composite brakes have their own characteristics of the use of maintenance.

The main features of carbon-carbon brake discs

1). Carbon-carbon brake disc density is 1 / 4-1 / 5 of steel. Because the brake weight is lighter than steel about 40%. The Aircraft performance improved significantly.

2). The Specific heat, thermal expansion coefficient is small, high strength stable at high temperature, so deformation and melting will not occur.

3). Friction and wear performance is good. The use of wear and tear is about 25% -50% of steel. Ordinary military machine has life of 1000 times ups and downs, the civil aircraft up to 3000 times ups and downs. Carbon-carbon brake discs wear to the limit size, you can also renovation.

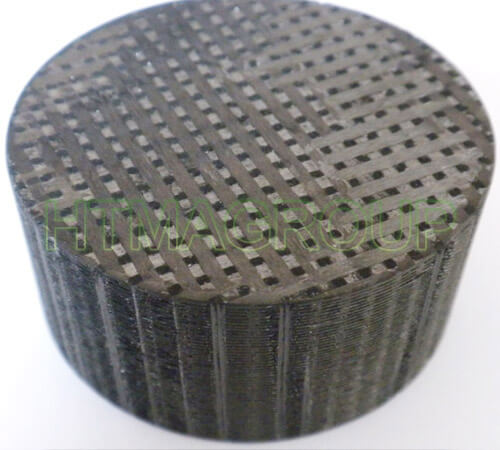

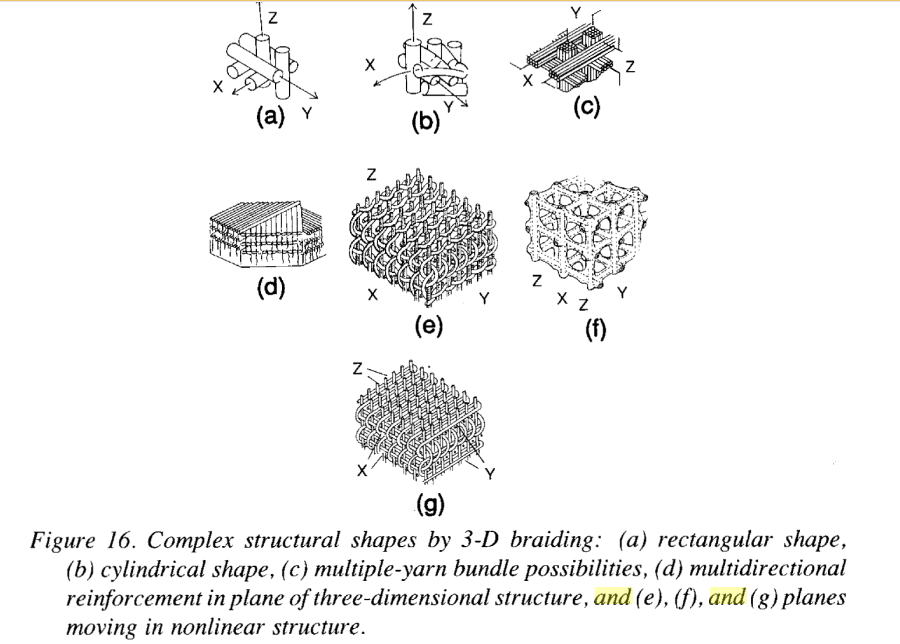

What is 3D carbon carbon composite? Its with 3 directions of carbon fibers, x,y,z directions. Sometimes we call it 3D xyz structure. See structure attached. Another type of 3D carbon structure is 3D hoop structure: with fibers in axial, radial and hoop directions. There are also other types of 3D structures. See bellow drawing too.

CFCCARBON LTD is a professional manufacturer of carbon composite. With density up to1.9-1.95g/cm3. We can produce carbon composite with required structures.

What is 4D carbon carbon composite? Strictly speaking, its 3D. Its with one more fiber in the plane direction. We call it 4D, which the customer wanted. See attached the drawing and the photos.

You can see a video bellow, a pitch based carbon composite product, which is with high density more than 1.90g/cm3. You can see the fiber orientation too:

Our Products were sold throughout the country and exported to Europe, America, Southeast Asia and other countries and regions which enjoy a high reputation all over the world. We hope to establish a good business relationship with you; we will serve you with the best quality, best delivery time and best solutions

Related products /news:

Different structures of Carbon carbon composite

Introduction of high-temperature coatings on CC composite material

Introduction of carbon-carbon (CC) material–CFCCARBON LTD

-hoop-structure-carbon-carbon-composite.png)