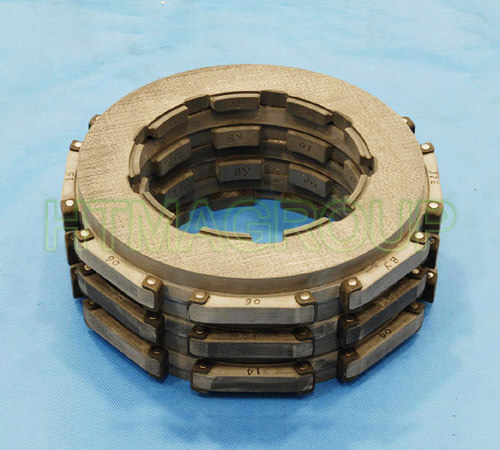

Carbon carbon composite aircraft brakes/brake disc/ brake disk

We can produce all typess of airplane brake disk and plates, our products have been used successfully for many years in the civil aviation aircrafts, quality is stable. .Our factory is government controlled company, and we are mainly engaged in research, development, production, sales of carbon carbon composite.

Detailed description

We can produce all types of airplane brake disk and plates, our products have been used successfully for many years in the civil aviation aircrafts, quality is stable. .

Our factory is government controlled company, and we are mainly engaged in research, development, production, sales of carbon carbon composite.

CFC Aircraft brakes/ disc/ Disks has advantages of long lasting lifetime, low competitive costs, more clean…

We can do X-RAY tests and other tests.

We can produce with all shapes of CFC Aircraft brakes/ disc/ Disks, as per customers’ special request.

Quality guaranteed and competitive prices. Code: B757-200, for Boeing 757; Also, we provide brakes for airbus, C919.

In December 2003, the company first get the Production of ratification of the B757 aircraft carbon brake pair parts in China, issued by the civil aviation administration of China, make our country the fourth with independent intellectual property rights in the world manufacturing carbon brake deputy country, after the United States, Britain and France, which has broken the western monopoly on China’s carbon brake market. So far, the project won 11 national invention patent, the product filled the domestic blank. “The preparation of high performance carbon carbon aircraft brake materials technology” was awarded the first prize for 2004 state science and technology invention.

standard data sheet of carbon composite brake disk:

| ITEM | UNIT | 2.5D |

| Bulk density | g/cm3 | ≥1.78 |

| Carbon content | % | ≥99.99% |

| bending strength | Mpa | 140 |

| Compressive strength | Mpa | ≥180 |

| interlaminar shear strength | MPa | >15 |

| Thermal conductivity | W/mk | 20~80 |

| coefficient of dynamic friction | 0.24-0.42 (adjustable) | |

| coefficient of static friction | 20.6MPa 3000psi | ≥0.16 |

| Inertial platform linear wear | Um/time/face | ≤1.5 |

| Processing temperature | ℃ | >2000 |

| Ash content | ppm | ≤100 |

| Metal ash content | ppm | ≤50 |

The main features of carbon-carbon brake discs

1). Carbon-carbon brake disc density is 1 / 4-1 / 5 of steel. Because the brake weight is lighter than steel about 40%. The Aircraft performance improved significantly.

2). The Specific heat, thermal expansion coefficient is small, high strength stable at high temperature, so deformation and melting will not occur.

3). Friction and wear performance is good. The use of wear and tear is about 25% -50% of steel. Ordinary military machine has life of 1000 times ups and downs, the civil aircraft up to 3000 times ups and downs. Carbon-carbon brake discs wear to the limit size, you can also renovation.

We can produce with all shapes / structures of 2.5D C/C composite aircraft brakes/brake disc/ brake disk as per customers’ special request.

We can produce as per coming drawings, we can produce as per coming samples and required properties of CC composite brakes; Ensure the quality, guarantee the reasonable price, ensure accurate delivery date! We can give low prices of carbon fiber composite airplane brake disc materials, more video please see below:

Related products /news:

C/C composite aircraft brakes | brake disc manufacturer in China

Data sheet of C/C composite for airplane brakes/disc